-

应力路径变化对于煤岩体变形与强度影响已经有学者进行了大量的研究分析[1-2].煤岩体为多孔介质,瓦斯气体在煤岩体的流动规律受控于多种因素,其中应力场改变特征是广大学者关注的焦点,也进行了大量的研究.

朱卓慧等[3]针对型煤试样进行了不同应力加载过程的渗透性测试,实验得到了轴压、围压、渗透压与渗透率的定量化关系,认为应力路径对于瓦斯渗透性有重要的影响;尹光志、许江等[4-10]对含瓦斯不同应力路径下瓦斯渗透性进行了大量的研究,得到了煤岩体渗透性在卸围压等条件下的规律;薛东杰等[11]利用相似材料模拟分析采场的应力分布,构建了渗透率与体积应变之间的关系;袁曦等[12]针对含瓦斯煤进行了3种不同应力路径下的瓦斯渗透性实验,得到卸荷路径、偏应力、体积应变及能量演化与渗透率关系;薛熠等[13]对于含瓦斯煤渗透性峰值前与峰值后对比的基础上提出了含有损伤特性的渗透率演化模型并进行了实验验证;张东明等[14]针对顶板砂岩进行了恒轴压卸围压的瓦斯三轴渗流实验,得到了砂岩的变形破坏规律及渗透性演化特征;田坤云等[15]对轴压围压加载作用下低渗透性煤层渗透性进行了实验研究.

纵观前人的研究成果不难得知,尽管有学者对原煤和型煤的渗透率做了一些具体研究,但对于瓦斯灾害频发的构造煤卸荷渗流特性缺乏研究,特别是构造煤与原生结构煤在不同应力下的渗透性对比分析研究较少.本文以山西晋煤集团阳城晋圣润东煤业3号煤层与河南西部受嵩山地质构造影响的软煤原煤样为研究对象,进行常规三轴加载与增轴压卸围压渗透性测试,结合实验结果,比较分析了两者的差异,以期对煤层瓦斯治理有一定的理论指导意义.

HTML

-

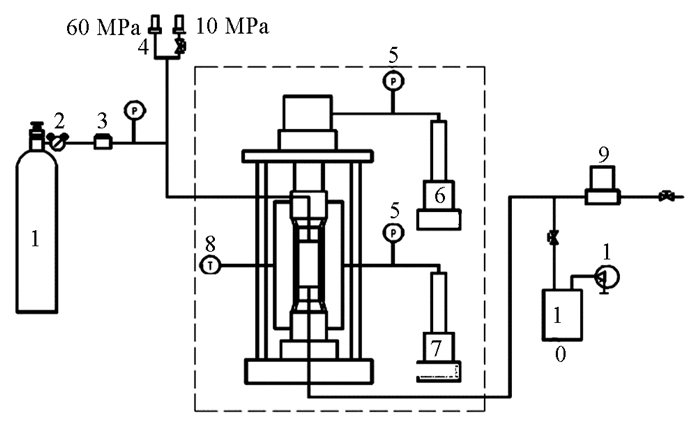

试验采用河南工程学院自行研制改造的含瓦斯煤热—流—固耦合三轴渗流试验装置[16],如图 1所示.煤样的安装如图 2所示.

-

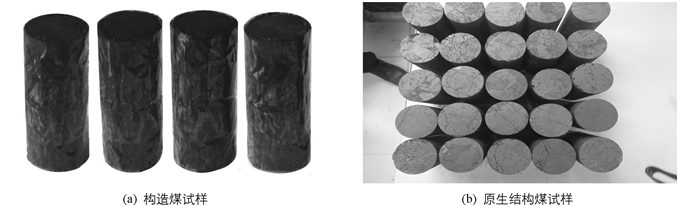

原生结构煤煤样取自山西晋煤集团阳城晋圣润东煤业3号煤层,工业性分析得到煤的水分为1.92%、灰分为15.1%、挥发分为7.8%和固定碳为75.18%.

构造煤取至河南西部矿区,国投能源新登煤矿二1煤层.煤质工业分析,煤的水分为1.95%、灰分为14.91%、挥发分为7.38%和固定碳为75.76%.

根据《水利水电工程岩石试验规程》(SL 264-2001)以及国际岩石力学学会推荐标准,试样制取的尺寸为:直径50 mm,高度100 mm的圆柱体.加工好的部分煤样见图 3所示.

-

试验前对煤样进行了筛选,采用声发射装置选取纵波波速相近的煤样进行试验,每组3个样,以保证获取试验的普遍规律.试验为获取两种煤样在常规三轴加载与增轴压卸围压路径下的渗透性规律为目的展开,两种路径下的试验方案如下:

1) 常规三轴加载渗透性测试

煤样置于上下为透气性环形压头的三轴夹持器中,轴压围压按照0.5 MPa/s中的加载速率加载至预定值,保持轴压围压不变,开启瓦斯压力进口为1 MPa,进行煤样的吸附及渗流平衡24 h.轴压采用位移加载,以0.01 mm/s进行加载,直至试样出现破坏,测量其变形及瓦斯流量变化.设置围压为2,4,6 MPa,瓦斯进口压力值恒为1 MPa.

2) 增轴压卸围压渗透性测试

轴压围压按照0.5 MPa/s的加载速率加载至预定值,保持轴压围压不变,开启瓦斯压力进口为1 MPa,进行煤样的吸附及渗流平衡24 h.轴压以0.5 MPa/s速率加载此围压强度极限的80%,轴压以0.5 MPa/s速率加载的同时围压以0.5 MPa/s速率进行卸载,直至煤样破坏,保持破坏围压不变,轴压以0.01 mm/s速率进行位移加载,直至出现残余强度,测量整个过程的煤样的变形与瓦斯流量变化.考虑卸围压渗流过程,卸载后围压值不能低于煤样孔隙压力值,设置围压分别为4,6,8 MPa,进口瓦斯压力恒为1 MPa.

1.1. 试验装置

1.2. 试验样品

1.3. 试验方案

-

煤样渗透性的主要参数为渗透率k(mD),其计算公式为

式中:μ为瓦斯气体动力黏度系数(Pa),p0为标准大气压(Pa),Q0为标准大气压下的渗流量(cm3/s),L为煤样的长度(cm),p1为煤样上端面进口瓦斯压力(Pa),p2为煤样下端面出口处负压(Pa),S为煤样横断面面积(cm2).

-

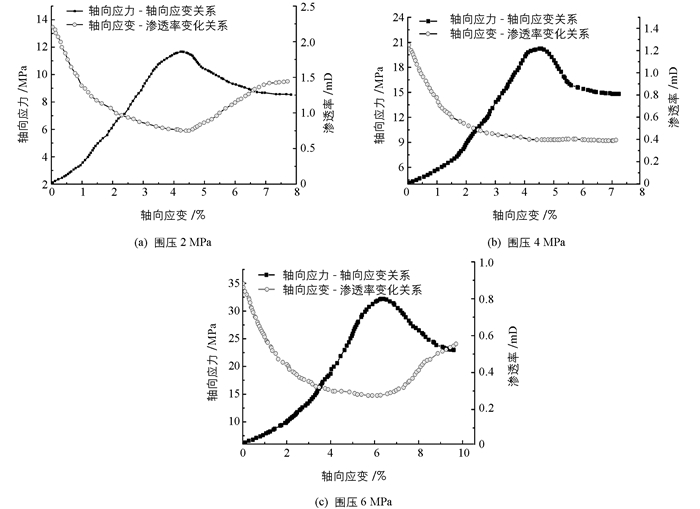

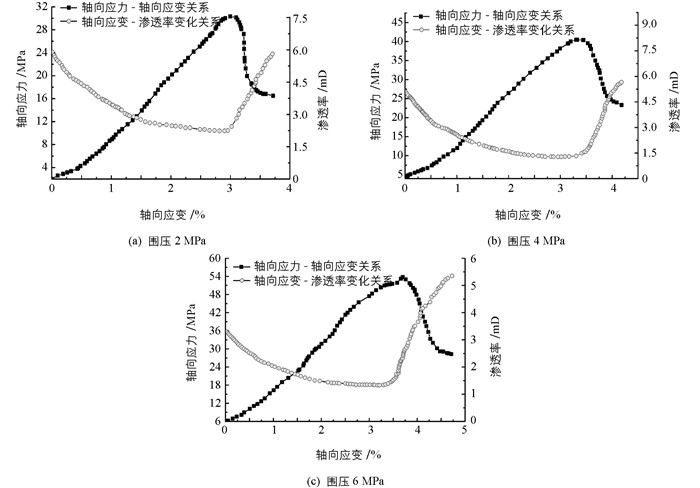

图 4给出了构造煤煤样围压分别是2,4,6 MPa时渗透率—轴向应变及轴向应力—轴向应变关系变化.

图 5给出了原生结构煤煤样围压为2,4,6 MPa时渗透率—轴向应变及轴向应力—轴向应变关系变化.

对比构造煤与原生结构煤煤样全程应力应变过程变形特征及渗透性演化特征可以发现有如下特点:

1) 从变形特征可以看出,两种煤样在全程应力应变曲线过程中有较为明显的阶段性,可以分为压密阶段、弹性阶段、屈服阶段及破坏后阶段.两者的变形能力相差较大,相同围压下,构造煤煤样的最大应变是原生结构煤的2倍左右.构造煤在峰值强度后,承载能力出现较为平缓的变化过渡到残余强度,而原生结构煤出现明显的应力降,残余强度随结构的破坏出现大幅度的降低.

2) 从渗透性随应变演化过程来看,两种煤样在压密及弹性阶段,渗透率都随着有效应力的增加而降低,不同的是构造煤煤样渗透性在压密阶段较为敏感,渗透率随有效应力增加出现较为快速的下降.弹性阶段的渗透性变化较为缓和,出现比较一致的渗透率降低过程.在峰值强度处,构造煤煤样渗透率在峰值强度后出现增大趋势,围压在2 MPa和6 MPa时,渗透率沿平滑曲线慢慢增大,最后趋于稳定;围压4 MPa时,构造煤煤样渗透率一直减小,最后趋于稳定.对比原生结构煤煤样,在峰值强度之前,煤样渗透率出现增加趋势,峰值强度后,渗透率急剧增加,增速较大,在较小的变形过程中,渗透率出现量级式的跳跃增加.

-

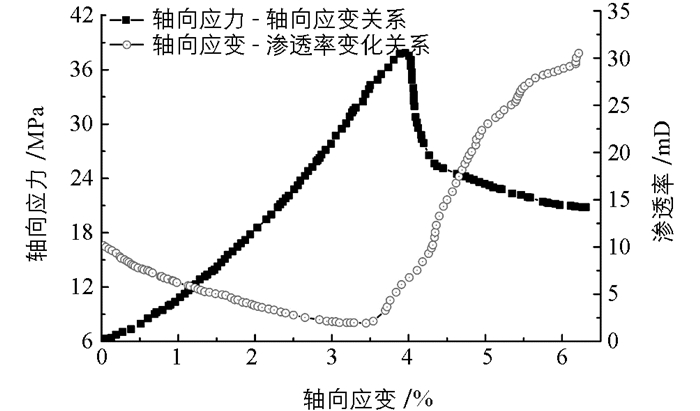

图 6给出了构造煤煤样在增轴压卸围压过程中的应力—应变及应变—渗透率的演化特征,图 7给出了原生结构煤煤样在增轴压卸围压过程中的应力—应变及应变—渗透率演化特征,限于篇幅所限,这里仅给出围压6 MPa时两种煤样的试验结果.

对比常规加载试验结果,针对增轴压卸围压两种煤样变性特征及渗透性变化可以看出,两种煤样在增轴压卸围压过程中峰值强度降低,构造煤煤样强度降低27%,变形能力增加18.6%.原生结构煤峰值强度降低29.7%,变形能力增加14.8%.

在渗透性演化方面,加载过程中,加载路径与常规加载相同,渗透率变化也表现出相同的特征,在增轴压卸围压阶段,两种煤样的渗透率增加速率均高于常规加载阶段渗透性变化速率,出现渗透率突变的特征.构造煤煤样渗透率在峰值强度后开始出现快速增加,原生结构煤渗透率在峰值强度前出现急速增长的趋势,随应变增加,渗透率增加,但增加速率降低.

-

结合试验数据发现,常规三轴加载渗透性测试与增轴压卸围压过程渗透性测试结果表明,两种煤样渗透性的差异主要集中在以下几个方面:

1) 煤体结构的不同

构造煤煤样在地质形成过程中,经受地质构造作用,基质颗粒的排列方式容易受应力控制进行进一步重组,重组后的颗粒间隙与原结构特征差异性较小,且部分构造煤强度较低,以煤粉形式进行的泥质胶结或碳质胶结形式存在,结构极易受到外力控制,由于其颗粒间的连接方式较弱,重构后的结构亦不易形成有效的流体通道,这也是构造煤在采动作用下瓦斯渗透性演化的特征.作为瓦斯防治的重点,构造煤在采动卸荷后,渗透性依然较低,这种构造煤对瓦斯的裹挟作用主要表现为有效孔隙通道未形成,且卸荷场形成的游离态瓦斯聚集形成瓦斯包,致使构造煤瓦斯灾害加剧的重要原因.笔者试验采用的构造煤煤样取自河南西部矿区,受嵩山地质构造作用,具有强度低,颗粒性较为明显,瓦斯吸附能力大等特征,试验过程中,在应力作用下颗粒间有明显的重组及流动作用,破坏后煤样的粉质结构特征明显.

原生结构煤强度较大,变形能力较弱,受地质构造作用不明显,质地较硬,有明显的裂纹存在,在受应力作用下易出现宏观裂缝,裂缝贯通形成有效的流体通道,这也是原生结构煤渗透率在屈服应力作用下出现增加原因所在,且形成的裂缝不易闭合,在有效应力的作用下,渗透率受有效隙宽的控制,所以在有效应力作用下,渗透率最终会趋于一稳定值.

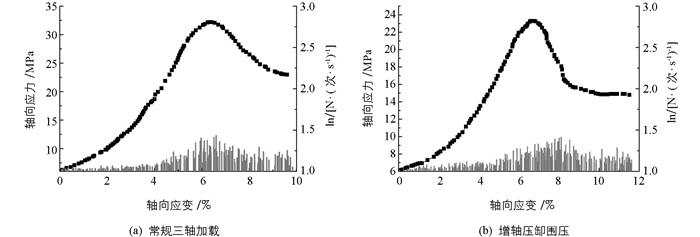

2) 裂隙扩展方式不同

为探究两种煤样不同应力路径下裂隙扩展情况,进行了受载煤样的声发射测试试验.从声发射AE计数与应变关系可以看出,构造煤煤样与原生结构煤煤样在应力应变过程中的声发射特征如图 8所示,仅给出了围压6 MPa作用下,构造煤与原生结构煤在常规加载及增轴压卸围压过程的声发射特征.

从图 8可以看出,构造煤煤样在常规三轴加载与增轴压卸围压两种不同的应力路径下,煤样的AE计数变化不大,声发射没有显著的增高或者是突然变化情况,表现为明显的塑性流动破坏情况,裂隙扩展未出现宏观的裂纹,随载荷增加,在峰值强度处,声发射计数虽有所增加,但并不显著.构造煤煤样在两种路径下的声发射特征表明,其破坏主要变现为煤基质颗粒的流动破坏,在整个应力—应变演化过程中,裂隙发展发育及进一步扩展的现象较弱.

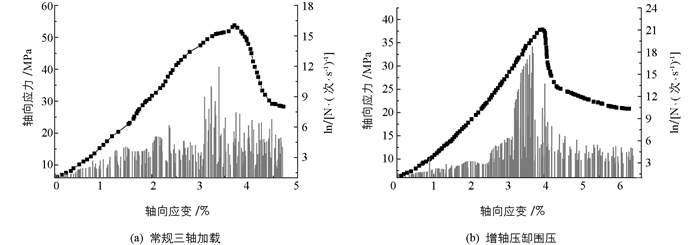

图 9为原生结构煤在常规加载与增轴压卸围压两种应力路径下的声发射计数变化,其变化有明显的阶段性特征.压密阶段,声发射事件发生,但程度不同,声发射计数较少,且幅值较小,这一阶段主要是煤样原始裂隙的受压闭合,裂隙面闭合过程的摩擦产生的声发射事件.弹性阶段的声发射事件数有一定的增加,但并未出现达到新裂隙扩展的应力水平,主要是原始裂隙闭合面之间的滑移产生的声发射现象.在煤样进入屈服阶段后,出现了煤样的损伤发展及裂纹的萌生,声发射事件发生出现大幅度的增加,煤样开始出现体积扩容现象,在峰值强度之前,微裂纹的萌生、扩展及进一步贯通,导致宏观裂纹的产生,多重裂纹之间的相互摩擦使此时的声发射事件异常活跃,破坏时煤样裂隙面的滑移及错动是导致这一阶段声发射事件较多的主要原因.对比两种应力路径可以得到增轴压卸围压过程声发射特征较常规三轴加载更为剧烈,事件数在各个阶段都高于常规三轴加载过程,这也表明增轴压卸围压过程原生结构煤破坏过程中裂隙的发展发育更为明显.

结合两种煤样声发射情况,煤样的瓦斯渗透性特征受控于内部裂隙萌生、发展及贯通的演化.构造煤煤样在常规三轴加载与增轴压卸围压两种应力路径下瓦斯渗透性变化从开始阶段减小,在煤样峰值强度后,出现渗透性缓慢增加,最后趋于稳定值,其渗透性在整个应力—应变过程变化不大,而且煤样在围压4 MPa作用下渗透性在煤样破坏阶段并未出现增大现场,究其原因认为构造煤受载破坏过程裂隙的发展并未形成有效的瓦斯通道.

原生结构煤煤样在两种应力路径下,渗透性也从压缩作用下的减小到煤样接近破坏或破坏后突然增大,最后受裂隙宽度控制趋于较高稳定值.不同的是,常规三轴加载煤样在接近峰值强度或峰值强度后出现渗透性的猛增,增轴压卸围压渗透率出现突变的点为屈服应力处,且增轴压卸围压路径下渗透率突变速率较大,煤样出现渗流突变特征,对比构造煤煤样,渗透性在破坏阶段的渗透率变化不大,渗透率速率变化较小.

2.1. 常规三轴加载渗流测试试验结果

2.2. 增轴压卸围压过程渗流测试试验结果

2.3. 两种煤样不同应力路径下渗透率差异性原因分析

-

通过对构造煤与原生结构煤两种煤样的常规三轴加载渗流与增轴压卸围压渗流测试试验,基于试验结果,得到如下结论:

1) 试验所采用的构造煤变形能力较大,是原生结构煤的数倍,然变形与渗透率不是递增函数的变化趋势,都有随变形先减小后增大趋势.对于构造煤而言,渗透率的演化受变形的控制较弱,变形表现为颗粒间的流动和体积扩容,渗透性随变形增加出现较为缓和的变化.

2) 构造煤瓦斯渗透性的变化受应力路径影响较弱,试验在两种应力路径下,构造煤瓦斯渗透性相同,渗透率在煤样破坏后出现一定的程度的增加,但并未突变,究其原因认为是构造煤特殊的颗粒粉质结构在载荷作用下的重组及裂隙未贯通而导致的.

3) 增轴压卸围压作用下原生结构煤破坏更为剧烈,瓦斯渗透性在屈服应力处出现反转,瓦斯渗流速率变大,在峰值强度处达到最大,渗透率与应变曲线在屈服应力后出现急剧上扬的态势,瓦斯渗透率发生突变,从原生结构煤裂隙萌生、扩展及贯通角度解释了煤样发生渗透性突变的根本原因.

DownLoad:

DownLoad: