HTML

-

不同透气度的5种卷烟纸、5种接装纸、5种成型纸,不同规格的3种滤嘴丝束.由于烟用醋纤丝束规格通常表示为单丝线密度/总丝线密度,导致在实验数据处理时无法作为单一指标来进行量化,因此本文在数据处理时统一采用丝束纵向表面积等效描述指数I来代替[12],即I=总丝线密度/

$ \sqrt {单丝线密度} $ .辅材均由重庆中烟工业有限责任公司提供.某牌号烤烟型叶组配方烟丝(重庆中烟工业有限责任公司提供). -

氢氧化钠(HPLC级,北京迪马科技有限公司);邻苯二甲酸氢钾(HPLC级,天津市富宇精细化工有限公司);异烟酸(百灵威试剂公司);氰化钾(HPLC级,天津市恒兴化学试剂有限公司).

-

RM20H/CS转盘式吸烟机(德国Borgwaldt公司);HY-8旋转震荡器(上海福玛设备有限公司);PL203电子分析天平[感量:0.0001 g,梅特勒-托利多仪器(上海)有限公司];Milli-Q超纯水系统仪(美国Millipore公司);SKALAR流动分析仪(荷兰,SKALAR公司).

-

按照实验设计进行实验时,除表 1中考察的因素外,烟丝及其余的卷制参数保持一致;卷制的烟支圆周为(17.0±0.2) mm、硬度[(60.0~65.0)±12.0]%及单支质量[(0.50~0.52)±0.05] g均在规定的允许误差范围内使用.

-

依据行业标准YC/T 253-2008[13],用连续流动分析法检测细支卷烟主流烟气中氢氰酸的释放量.

-

以细支卷烟卷接材料卷烟纸透气度(X1)、接装纸透气度(X2)、成型纸透气度(X3)、滤嘴丝束规格(X4)为考察因素[14],以氢氰酸释放量为指标,采用“基于均匀设计的计算机辅助设计”设计实验方案[15-16],其因素及水平见表 1.

-

使用SPSS和DPS统计分析软件,以卷烟主流烟气中氢氰酸释放量为因变量,采用二次多项式逐步回归建立模型,并进行检验;采用文献[17]的方法计算各要素的贡献率;运用基于实际参数的极值寻优方法和综合平衡法[18-21],得到主流烟气氢氰酸释放量较低的参数优化组合,并进行验证.

1.1. 材料、试剂与仪器

1.1.1. 材料

1.1.2. 试剂

1.1.3. 仪器

1.2. 方法

1.2.1. 细支卷烟卷制

1.2.2. 氢氰酸的检测

1.2.3. 实验设计

1.2.4. 数据处理

-

根据表 1设计的实验因素及水平,使用不同参数指标的材料卷制了6组样品,每组实验样品进行3次重复测定并取其平均值(表 2).由于各因素的量纲和数量级不一致,为便于统计分析,采用极差归一化变换[22]对实验设计的各因素水平进行变换,即各因素水平的变换值C=(X-Xmin)/(Xmax-Xmin),实验检测结果见表 2.

从表 3可知,不同卷烟材料组配得到的卷烟样品其主流烟气中氢氰酸的释放量偏度系数略大于0,表现为正偏峰,且峰度系数略小于0,表现为平阔峰,整体数据稍显分散;标准差和变异系数均较小,偏度系数和峰度系数均接近于0,说明该数据统计结果基本符合正态分布特征,可以将其作为一个整体进行分析评价.

-

将实验设计的各因素设为自变量,细支卷烟样品主流烟气中氢氰酸释放量为因变量,采用二次多项式逐步回归方法得到模型

因素与主流烟气氢氰酸释放量的决定系数R2=0.999 9,说明模型拟合度好;对模型进行F检验,F=2 683.37>F0.05(4,1)=224.58,表明该回归方程达到显著水平,具有统计学意义;对模型进行T检验,P=0.014 < 0.05,表明方程中各自变量的系数均达到显著水平;进行模型的残差独立性检验,Durbin-Watson统计量d=2.31,说明残差间无自相关,表明模型具有很强的解释能力. 表 4为目标值的标准回归系数,反映了各因素或因素交互作用对目标值的影响程度[23]. X2,X1X4与细支卷烟主流烟气氢氰酸释放量呈负相关,X22,X3X4与细支卷烟主流烟气氢氰酸释放量呈正相关.

-

采用因子主效应分析法计算各因子对因变量的贡献率,该贡献率表征的是在整个实验范围内各因子的贡献大小.经计算得到各要素的贡献率分别为卷烟纸透气度0.482 0、接装纸透气度1.949、成型纸透气度0.459、滤嘴丝束规格0.941.结果表明,接装纸透气度对细支烟主流烟气氢氰酸释放量影响最大,在卷烟材料规格设计中需着重考虑;其次分别是滤嘴丝束规格、卷烟纸透气度和成型纸透气度.

-

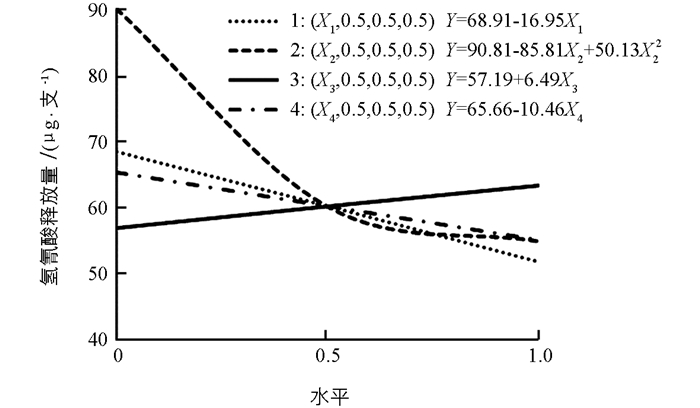

为深入研究其他因素在不同水平时某特定因素对细支卷烟主流烟气中氢氰酸释放量的影响规律,将模型中各因素划分为高(1.0)、中(0.5)、低(0)3个水平,并对以上实验结果进行单因素分析.设定除分析因子外的其他因子为中水平(0.5),根据回归方程(1)分别得到各因子与细支卷烟主流烟气氢氰酸释放量的关系,如图 1所示.

从图 1可以看出,在其他因素为中水平(0.5)时,不同因素对主流烟气氢氰酸释放量的影响趋势存在差异.在实验参数设定范围内,接装纸透气度X2与细支卷烟主流烟气中氢氰酸的释放量呈曲线相关,通过求二次方程曲线对称轴的方法得知,X2=0.856时出现拐点.由此可见,当0≤X2 < 0.856时,接装纸透气度(X2)与氢氰酸释放量呈曲线负相关,当0.856 < X2≤1时,接装纸透气度(X2)与氢氰酸释放量呈曲线正相关;卷烟纸透气度X1和滤嘴丝束X4与氢氰酸释放量呈直线负相关关系;成型纸透气度X3与氢氰酸释放量呈直线正相关.

-

为比较各因子对细支卷烟主流烟气中氢氰酸释放量影响的速率,对回归分析模型(1)中各因子求偏导,同样将分析因子外的其他因子取中水平(0.5),得到各因子边际主流烟气氢氰酸释放量的效应关系式(表 5).由表 5可知,在实验参数设定范围内,各因子对主流烟气氢氰酸释放量的影响速率分别为卷烟纸透气度(X1)和滤嘴丝束规格(X4)呈负效应,成型纸透气度(X3)呈正效应,且不随其水平变化而变化;当0≤X2 < 0.856时,接装纸透气度(X2)与氢氰酸释放量呈负效应,当0.856 < X2≤1时,接装纸透气度(X2)与氢氰酸释放量呈正效应;成型纸透气度(X3)对氢氰酸释放量影响速率的绝对值随其水平增大先减小到0后再增大,说明随着接装纸透气度的水平从0增加到0.856,其对氢氰酸释放量的影响速率逐渐降低,接装纸透气度的水平从0.856增加到1时,其对氢氰酸释放量的影响速率逐渐增大.

-

通过因子主效应分析、单因素分析和边际效应分析可知,在实验范围内卷烟纸透气度、接装纸透气度、成型纸透气度、滤嘴丝束规格对细支卷烟主流烟气氢氰酸释放量的影响显著,且呈现不同的规律.因此,需要对参数组合进行寻优,找到细支卷烟主流烟气中氢氰酸低释放量的卷烟材料参数组合.

-

使用SPSS统计分析软件,基于实际参数范围内的极值寻优方法和综合平衡法,对主流烟气氢氰酸释放量的二次模型进行求解,得到了氢氰酸释放量较低的卷接材料组合,即当X1=1,X2=0.75,X3=0,X4=1时,细支卷烟主流烟气中氢氰酸的释放量较小.经反归一化得到的优化参数组合为卷烟纸透气度100 CU、接装纸透气度800 CU、成型纸透气度6 000 CU,滤嘴丝束规格6.0 Y/17000.

按上述优化参数组合进行3次验证试验,分别测定细支卷烟样品主流烟气氢氰酸释放量,结果见表 6.

由表 6可以看出,前述优化参数组合得到的细支卷烟样品主流烟气氢氰酸释放量较低,且与模型预测值有很好的一致性,相对偏差小于10%.

2.1. 实验结果

2.2. 构建逐步回归分析模型

2.2.1. 实验因子主效应分析

2.2.2. 单因素对氢氰酸释放量的影响

2.2.3. 各因子的边际主流烟气氢氰酸释放量效应

2.3. 综合分析、参数优化与验证

2.3.1. 综合分析

2.3.2. 参数优化与验证

-

1) 本文应用多种数据分析方法研究了卷烟纸透气度、接装纸透气度、成型纸透气度、滤嘴丝束规格对细支卷烟主流烟气氢氰酸释放量的影响规律.模型的标准化回归系数从大到小依次为接装纸透气度、接装纸透气度的平方、卷烟纸透气度和滤嘴丝束规格的交互作用、成型纸透气度和滤嘴丝束规格的交互作用,接装纸透气度、卷烟纸透气度和滤嘴丝束规格的交互作用与细支卷烟主流烟气氢氰酸释放量呈负相关,接装纸透气度的平方、成型纸透气度和滤嘴丝束规格的交互作用与细支卷烟主流烟气氢氰酸释放量呈正相关.

2) 各因子对细支卷烟主流烟气中氢氰酸释放量的贡献度大小顺序依次为接装纸透气度、滤嘴丝束规格、卷烟纸透气度、成型纸透气度.接装纸透气度对氢氰酸释放量影响最大,且呈负相关,这与卷烟材料参数影响常规卷烟主流烟气中氢氰酸释放量的研究结论一致[24-26],因为增加接装纸透气度可以有效稀释卷烟烟气,进而降低主流烟气中有害成分的释放量.当其他因子取中水平(0.5)时,滤嘴丝束规格对氢氰酸释放量呈负相关,随着滤嘴丝束规格增大,丝束纵向表面积增大,滤嘴对主流烟气中氢氰酸的过滤能力增强,从而降低氢氰酸的释放量;与卷烟材料参数对常规卷烟主流烟气中氢氰酸释放量影响方式不同的是,细支卷烟成型纸透气度与氢氰酸释放量呈直线正相关关系;通过极差反归一化换算,接装纸透气度对细支卷烟主流烟气氢氰酸释放量的影响在884.8 CU处出现拐点,先呈负相关,再呈正相关,影响速率绝对值随其水平增大在同样的拐点先减小到0再增加.因此,结合卷烟设计和生产实际情况,适当增加卷烟纸的透气度,选择接装纸透气度在884.8 CU附近,较大的滤嘴丝束规格,可在一定程度上降低细支卷烟主流烟气中氢氰酸的释放量.

3) 通过综合分析,得到了细支卷烟主流烟气中氢氰酸释放量较低时的卷烟材料参数优化组合,并使用优化后的材料组合进行样品卷制验证.

4) 以上研究结论是针对同一叶组配方以及采用相同生产工艺流程制得的细支卷烟样品得出的,是否适用于实验范围以外的情况还需进一步验证.

DownLoad:

DownLoad: