-

近年来,我国禽畜养殖产生的粪污达38亿吨,造成了严重的面源污染,同时也使猪粪等固废的处理迫在眉睫. 好氧堆肥化作为处理有机固体废物的主要技术之一,可同时实现废物的无害化、减量化和资源化[1].

但传统的堆肥方式存在周期长、腐殖化程度不高、氮素损失严重等问题,添加剂是解决此类问题的重要途径[2]. 常用的添加剂有:木灰、石灰等调控pH值的碱性物质[3-5];尿酸、竹醋及木醋等调控pH值的酸性物质[6-7];竹炭、木炭及秸秆碳等生物炭类物质[6, 8-9];镁盐、铁盐及磷酸盐等化学物质[10-12]和菌剂[13]. 生物炭由于其巨大的比表面积和孔隙率使其被加入堆体后可以增加微生物活性和改善堆体的供氧环境. 相比于木炭、秸秆炭等,竹炭因比表面积更高受到青睐[14]. 竹醋作为竹炭生产的副产物,由于其能调控堆体的pH值,也得到广泛关注.

氨氮在pH值较高的条件下更容易挥发,而禽畜粪便堆肥初期的堆体pH值常常为弱碱性,氮损失量大. 为降低堆肥pH值,常添加竹醋和木醋等小分子有机酸[15]. 但Maillard反应及多酚聚合等腐殖质合成理论认为,羧酸、酚以及还原糖等小分子有机物是腐殖质合成的前驱体[16],因此对富含羧酸、多酚的竹醋作为堆肥添加剂的研究不应只停留在其对保氮的作用,还应该进一步探讨其对堆肥腐殖化进程的影响. 值得注意的是,堆肥时期不同,产生的营养组分差异会导致微生物活性及群落的变化,进而改变腐殖质的生成和聚合程度. 但是,将竹醋作为腐殖质的前驱体,在堆肥不同阶段加入后,对堆体的腐殖质形成有何种影响鲜有报道.

为此,本研究在堆肥初期加入竹炭,在堆肥初期、高温期和降温期分别加入竹醋,研究其添加时期对堆肥腐熟和腐殖化进程的影响,为堆肥中腐熟指标及有机肥的生产提供一些新的思考.

HTML

-

新鲜猪粪取自于重庆合川区养猪场,杨木木屑(堆肥调理剂)购于江苏省连云港,竹炭、竹醋购于浙江省遂昌县神龙谷碳业有限公司.

-

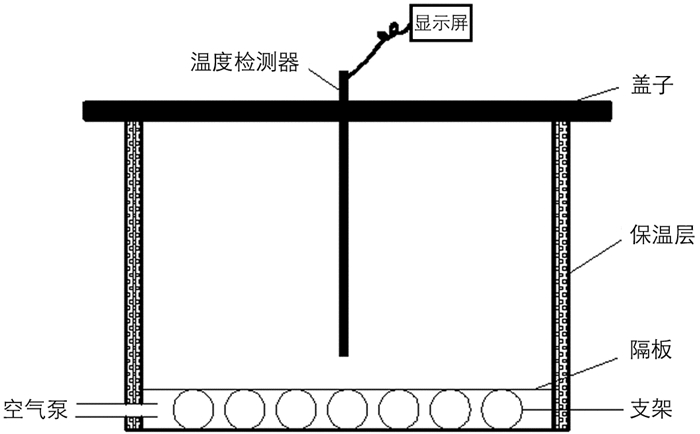

堆肥装置(图 1)有效体积90 L,并包裹橡塑海绵进行保温,在反应器底部铺设曝气管通风,空气从底部泵入,平均流量0.1 L/min,堆肥时长为60 d,并持续通风,堆肥装置如图 1所示. 每个堆体总质量为26 kg,用木屑调节水分至60%,C/N至20,竹炭于堆肥初期添加,添加量为堆体总质量的3%,竹醋分别于堆肥初期(第0 d)和高温期(第7 d)以及降温期(第14 d)投加,投加量为堆体质量的1%.

为保证堆体均匀且减少厌氧区,每周进行一次人工翻堆,堆体温度分别于每天9:00,15:00和21:00进行测量. 分别在0,3,7,14,21,30,45,60 d进行采样,将取得的样品分为两部分:一部分作为鲜样存放在4 ℃的环境中,另一部分在自然状态下风干并粉碎,过0.15 mm筛备用.

-

pH值、电导率(EC)、氨氮(NH4+-N)、种子发芽指数(GI)采用鲜样进行测定[17];EC、pH值以及GI用纯水以1∶10(w/v)进行浸提后测量,GI计算公式如下:

NH4+-N用2 mol/L KCl进行浸提后采用靛酚蓝显色法测定;总有机碳(TOC)、总凯氏氮(TKN)、腐殖质(HSC)等采用风干样品测定,有机碳采用高温外热重铬酸钾氧化法测定;总凯氏氮(TKN)采用凯氏定氮法[18]测定;腐殖质(HSC)、富里酸(FAC)、胡敏酸(HAC)质量分数(以碳计)采用国家标准NY/T1867-2010测定.

反应腐殖化程度的腐殖化系数则采用下面公式进行计算[19]:

1.1. 供试材料

1.2. 堆肥试验设计和取样

1.3. 试验指标测定

-

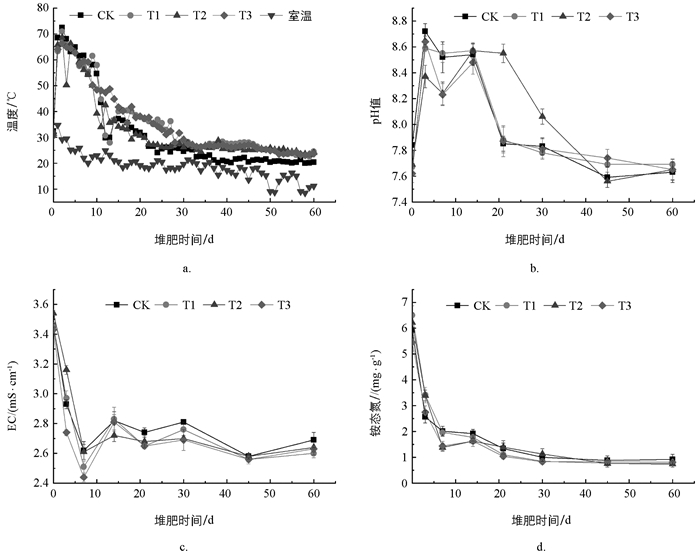

堆体温度是堆肥腐熟的基本要求,连续3 d大于55 ℃可以消灭大部分的病毒微生物和杂草种子[20]. 各堆体温度经历了3个典型阶段(中温、高温和腐熟阶段),温度2 d内就到达最高值(CK,T1,T2,T3分别为72.4,71.0,68.6,66.4 ℃),进入高温期,表明堆体中微生物活性快速提高,易分解有机物大量分解. 12 d后高温期基本结束,CK,T1,T2,T3处理堆体的高温期(50 ℃以上)分别为10,10,9,9 d,达到了5 d以上的腐熟要求[21]. 从各堆体温度情况看,竹醋的加入对堆体温度既无抑制作用也无促进作用,这可能是在初始阶段和高温阶段加入的1%竹醋的含碳量较低,而且微生物活性高导致分解速度较快,使温度无明显改变(图 2a),CK与T3在最高温度相差6 ℃可能是由于测量和随机误差所致(图 2).

各个堆体pH值随时间的进程呈现相似的变化趋势(图 2b). 所有处理堆体的pH值在堆肥初期相近(CK,T1,T2,T3分别为7.84,7.67,7.69,7.62),然后先急剧上升,再略微下降,再上升,进入降温期后出现明显的下降并逐渐趋于平稳. 堆肥高温前期,pH值急剧上升的原因在于猪粪中易分解的小分子有机酸的大量消耗,而高温期出现pH值波动是因为较难分解的有机物大量分解并产生小分子酸以及小分子有机酸的加入. 进入降温期后,pH值的下降可能是难分解的有机物进一步降解产生小分子酸,同时硝化作用产酸所致[22]. 与CK相比,竹醋加入的时间点未出现pH值下降的原因是先取样再加入竹醋,而堆肥结束时各堆体的pH值都低于堆肥安全利用推荐限值(pH值< 8.5)[21].

电导率(EC)值反映了堆体中的含盐量,而含盐量高的堆肥不仅会降低种子发芽率,施入土壤后还会影响作物的生长,因此堆体的EC值是一个必要检测的指标[23]. 试验发现,所有处理的EC值均呈现先快速下降后有所上升的变化趋势,第14 d以后EC值虽然有一些波动,但最后逐渐趋于稳定(图 2c). 第1周内EC值迅速下降然后增加,这可能是氨挥发和矿物盐沉淀[24],随后的升高可能与堆肥质量的净损失和通过有机物分解释放可溶性盐有关. LI等[25]的研究也有相似结论. 一般来说,堆肥的EC值≤4.0 mS/cm[21]就达到可安全使用要求. 本研究所有处理堆体最终EC值均在安全范围之内.

氨氮质量分数和堆体腐熟程度有着密切关系,氨氮质量分数过高导致游离的NH3存在,进而影响种子发芽或土壤微生物活性[26]. 所有处理铵态氮质量分数整体呈初期剧烈下降后期逐步稳定的变化过程(图 2d). NH4+-N显著降低是高温期氨氮的挥发和微生物的同化所导致[27];14 d后,氨氮进一步同化但由于氨氮总量减少,下降速率缓慢;最终,CK,T1,T2和T3的铵态氮质量分数分别为0.92,0.77,0.74,0.81 mg/g. 值得注意的是,在堆肥高温期加入竹醋的处理组氨氮质量分数下降缓慢,说明竹醋的加入在一定程度上延缓了氨氮的挥发,减缓了氮素损失.

-

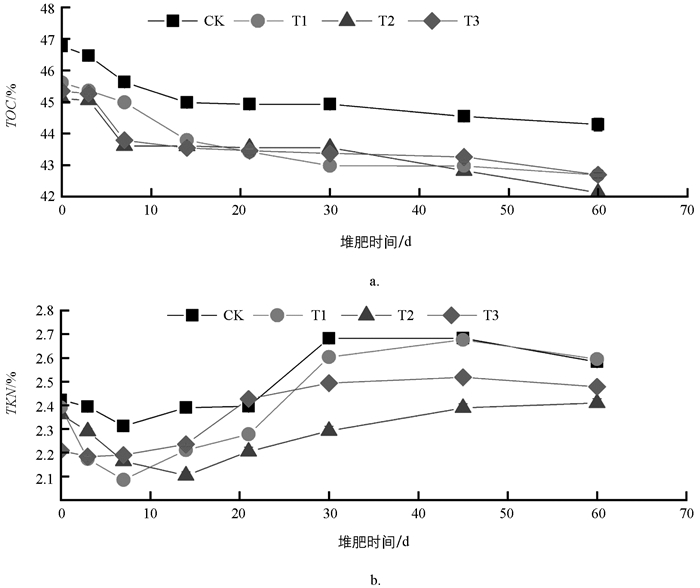

从图 3a可见,堆体总有机碳质量分数(TOC)随堆肥时间的进行逐步下降,CK,T1,T2,T3堆肥初始TOC比例分别为46.76%,45.61%,45.11%和45.35%,对比堆肥降温期及腐熟期TOC下降较为缓慢,高温期堆体TOC由于微生物活性较大,出现明显下降趋势. 堆肥降温期堆体TOC的下降速率放缓则是后期水分较低,导致微生物活性不高引起[28]. 对比4个堆体TOC降解率(TOC降解率=降解的TOC比例/初始TOC比例×100%)发现,第0 d和第7 d加入竹醋可明显促进TOC降解(T2-6.60%>T1-6.42%>T3-5.86%>CK-5.30%). 黄向东[15]研究发现,添加竹醋堆体微生物的Shannon指数均高于对照组,证明前期加入竹醋刺激了微生物活性,使降温期加入竹醋并未出现TOC明显下降.

TKN作为堆肥氮素最重要的成分,其值常用于有机肥品质的评价中. 从图 3b来看,各堆体TKN比例呈先下降后上升的变化趋势,堆体TKN先下降的原因是氨氮的高温挥发以及有机氮向无机氮方向转化[6]. 比较第0 d和第7 d加入竹醋的TKN曲线发现,T1曲线和对照曲线类似,在第7 d出现最低点,而T2曲线最低点却出现了滞后现象,这可能是第7 d加入竹醋为微生物提供营养促进了有机氮进一步矿化所导致的. 堆肥结束后TKN增长率(与第0 d相比)按顺序排列为:T3-11.66%>T1-8.17%>CK-6.07%>T2-1.82%. 增长率的变化说明了竹醋在不同时期的加入对氮素转化是有影响的,而单从增长率看,第14 d加入竹醋促进了微生物对氮素的同化. 而第7 d加入竹醋可能增加了微生物活性,促进有机氮的矿化,而且处于高温期,从而增加了NH3或NxO的挥发.

-

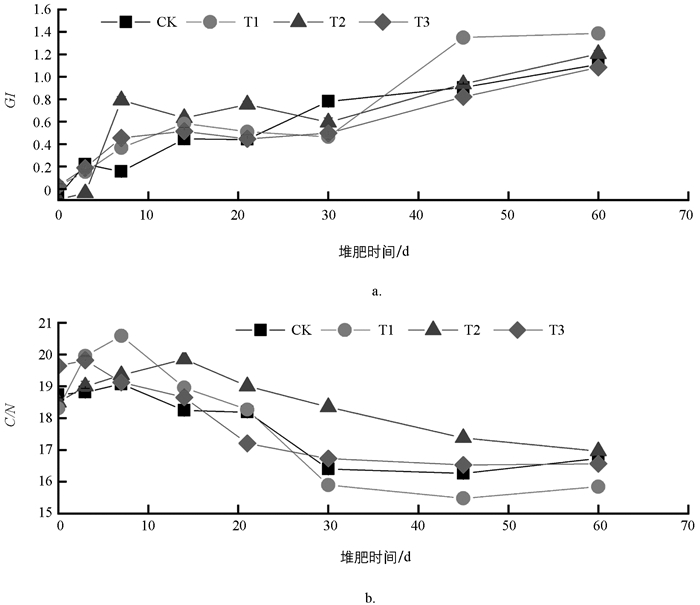

GI是一种综合性的生物指标,被认为是评价堆肥毒性和成熟度的最敏感参数[29]. 从图 4a看出,所有处理开始时的GI都小于0.4,随着堆肥的进行,所有处理的GI值呈现上升的趋势. 前期由于堆体的不稳定,具有较强的生物毒性(如高氨氮、高EC以及小分子有机酸等),而随着堆肥的进行,小分子有机酸分解,EC下降和腐殖化程度提高,使堆体逐步稳定,生物毒性降低[23];在堆肥结束时,CK,T1,T2,T3的GI值分别是1.14,1.35,1.23,1.08,最终所有处理的GI值均高于推荐值(50%)[21],且添加竹醋T1,T2的处理GI高于对照组,表明添加竹醋使堆体更加稳定和安全,生产的堆肥可作为有机肥用于农业生产(图 3a). 而T3处理在降温期加入竹醋,由于缺少高温条件,并不能促进有机质的进一步降解(图 3a),堆肥结束时(第60 d)其GI值和对照组相近.

碳氮比也是衡量堆肥品质的重要参数,它直接说明了最终产物是否会抑制植物生长[30]. 从图 4b看出,堆体C/N呈现先上升再下降的过程. 前期可能是因为高温期,易矿化有机氮大量分解转化为无机氮,氨氮挥发,使有机氮锐减,而有机碳的下降相比TKN变化缓慢导致C/N上升,随着无机氮逐步被微生物重新同化及有机碳下降明显,使得其C/N比持续下降;在堆肥结束时,CK,T1,T2和T3的C/N分别为16.73,15.84,16.96和16.56. 由此看出,经过长期的好氧堆肥对其影响并不大.

-

腐殖质作为土壤有机质的组成成分,因其对土壤理化性质调控、种子发芽、植物生长以及作物产量具有促进作用而受到关注,且胡敏酸作为腐殖质的组成成分,其稳定性和高阳离子交换量对土壤的解毒和抵御外来污染物起到了很重要的作用[31]. 因此将堆肥作为有机肥施入土壤时,其腐殖质比例和变化是需要关注的. 随着堆肥的进行,堆体理化性质发生剧烈改变,用单纯的富里酸、胡敏酸以及腐殖质比例变化具有一定的局限性. 因此引入腐殖化系数(HR)、腐殖化指数(HI)、胡敏酸百分比(PHA)和腐殖质聚合度(DP),使腐殖质变化与堆肥整体变化相结合,说明腐殖化进程[32].

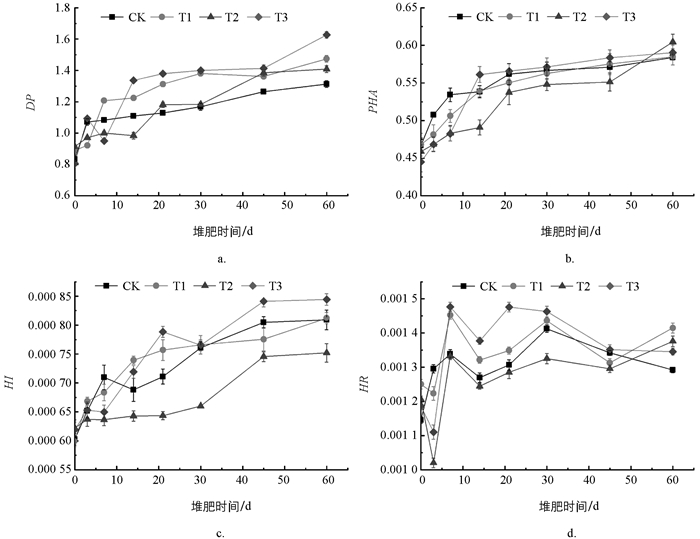

随着堆肥的进行,由于微生物的不断作用,简单的小分子有机物向复杂的更稳定的大分子有机物转化[33],虽然有机质不断减少,腐殖化系数(HR)却不断上升. 相比对照组的腐殖化系数的增加量(12.77%),竹醋的添加使其腐殖化程度更高(T1-14.90%,T2-15.98%,T3-18.34%). 值得注意的是,T3处理较T1,T2更能有效促进腐殖化系数的增加,且与胡敏酸相关的腐殖化指数(HI)也以T3处理最高(T3-38.28%,CK-34.28%). 其原因在于,堆体后期易分解物质大量减少,微生物群落结构变化且活性有所降低,此时加入竹醋,一方面可能再次提高微生物活性,促进难降解有机物继续分解生成更多的腐殖质前驱体,另外一方面小分子有机酸直接参与非生物的腐殖化进程,从而使得T3处理的腐殖化程度增加.

腐殖质聚合度(DP)由于能较好评价堆体的腐熟程度和腐殖质的聚合情况被广泛使用. 由于富里酸相比胡敏酸分子量小且稳定性差,较低的腐殖质聚合度(DP < 1)常被视为堆体未腐熟[21]. 从图 5来看,堆肥腐殖质的聚合度随着堆肥进行而不断上升,堆体的稳定性也在不断增强,从堆肥前后DP的增加率看,T3增加最为明显(T3-101.84%>T1-65.84%>CK-57.63%>T2-54.09%). 同样T3处理的PHA的增加率也是最高,堆肥结束后其HAC/HSC上升了32.71%. 综上4个指标可见,于堆肥第14 d加入竹醋(T3处理),并没有因为小分子有机酸的介入而导致堆肥腐熟度和腐殖化程度下降,反而增加了腐殖化系数和腐殖质的聚合程度.

Wang等[34]通过逐步调控环境因素,证明环境变化有利于腐殖质的生成. Zhu等[35]通过结构方程模型(SEM)分析发现还原糖和腐殖质的形成相关性有统计学意义,并且在中温期和腐熟期加入还原糖可以促进腐殖质的生成,本研究也出现了类似的结果. 从堆体腐熟程度指标(如C/N、GI)看,降温期加入竹醋(T3处理)与堆肥初期加入竹醋(T1处理)指标相比要低,但是也到达了安全利用的要求,而从腐殖化进程来看,堆肥后期加入竹醋使腐殖质和胡敏酸质量分数增加,同时提高了腐殖化程度,其作为有机肥长期施入土壤,会在一定程度改善土壤自身理化性质和结构. 竹醋作为添加剂在不同时段的加入为堆肥添加剂一贯单一时间段的添加(堆肥初期)提供了参考.

2.1. 竹醋对堆体基本理化的影响

2.2. 竹醋对堆肥TOC以及TKN的影响

2.3. 竹醋对堆肥腐熟度的影响

2.4. 竹醋对堆肥腐殖化的影响

-

堆肥初期加入竹醋可使堆肥结束后堆体C/N(15.84)最低、GI值(1.35)最高,氮素损失降低(TKN提高8.17%),即堆肥初期加入竹醋可以提高堆肥腐熟度和堆肥品质.

堆肥降温期(第14 d)加入竹醋,使堆肥得到的有机肥除满足正常的堆肥农用要求外,其腐殖化系数(18.34%)和腐殖质聚合度(101.84%)的增长率都高于其他处理.

竹醋的加入时间段对堆体的理化性质、腐熟度和腐殖化进程都有明显的影响,在降温期加入竹醋可有效提高堆体的腐殖化程度.

DownLoad:

DownLoad: