-

大气环境与人类新陈代谢的生命活动息息相关,随着我国经济发展和工业化进程的加快,近20年来,大气环境污染问题日益突出.自“十一五”以来,我国中东部等工业、人口活动密集地区持续受到雾霾天气影响,尤其是环境承载力相对较弱的华北平原,环保部出台了“2+26”城市大气污染防治三年作战计划.在所有影响大气污染的因素中,作为PM2.5前体物和导致光化学烟雾现象的挥发性有机污染物(Volatile Organic Compounds,VOCs)的排放日益受到关注. VOCs的来源主要包括涂装、医药和石化等行业,其中家具制造行业是VOCs的重要来源之一.随着国民经济发展和人民生活需要以及国际市场的要求,我国的家具行业呈井喷式增长. 2016年全国规模以上企业5 561家,主营业收入8 599.46亿元,同比增长8.57%;利润达537.48亿元,同比增长7.88%[1-2].木制家具作为家具制造行业的主要产品,其在涂料调配、面漆喷涂等生产工序中会大量使用有机溶剂,如树脂、胶粘剂、漆制涂料(硝基漆、不饱合聚脂漆、聚氨脂漆等)和催干剂等,这些材料和辅料中含有多种有机溶剂,具有较强的挥发性和毒性[3-5].家具生产各工艺环节中的VOCs以苯系物为主,(邻、间、对)二甲苯、甲苯等占比达78.6%以上[6].

目前,VOCs的处理技术主要可分为两类:一类是回收法,主要有吸收法、吸附法、冷凝法和膜分离法;另一类是消除法,主要有焚烧法、光催化降解法、生物降解法,以及等离子体技术[7-10].对于家具涂装这类有机污染物浓度相对较低(< 1000 mg/m3)的废气,将其降解是较理想的解决方案.其中,生物法是利用微生物活性,将VOCs类污染物作为微生物生命活动的碳源,以实现VOCs降解的技术[11-13].与其他工艺相比,生物法在节能降耗等方面具有潜在优势,尤其适于处理低浓度有机废气,可在保证净化效率的前提下,解决现有涂装废气治理技术存在的运行费用高、降解产物不彻底等问题,因此该工艺被认为是涂装废气污染控制领域中极具发展前景的技术之一[14].

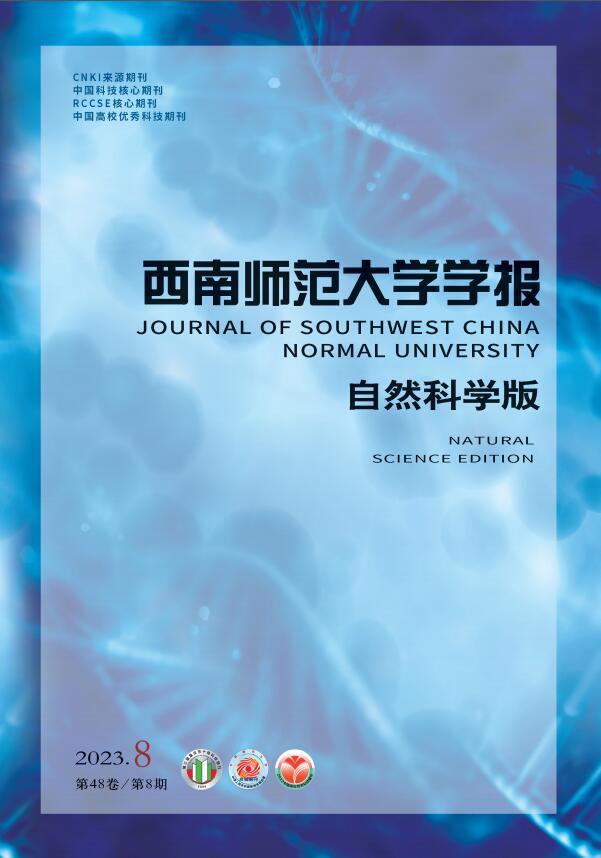

生物法的核心是高效微生物降解菌的培养.本试验模拟典型家具制造企业涂装车间喷漆废气中难降解的二甲苯3种同分异构体作为研究对象,设计最大处理风量为120 m3/h的生物滴滤塔处理装置,通过接种实验室前期已培育的不动杆菌属(Acinetobacter sp.,系统进化树见图 1),经调试和工艺参数的优化,探索出一种适合喷涂废气治理,且投资、运行成本较低的技术工艺.以期获得良好的经济、社会效益,最终实现该技术推广应用.

HTML

-

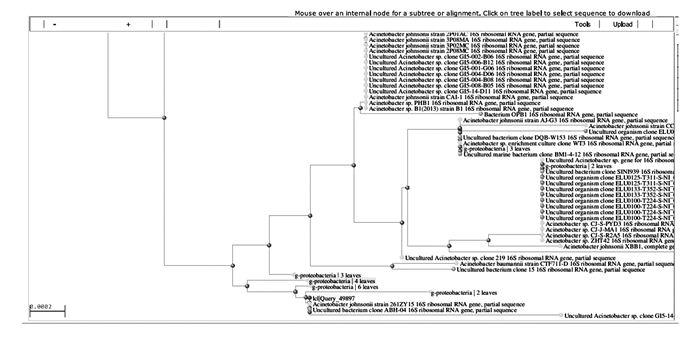

本试验装置主要由气体发生及控制单元、液体循环泵、滴滤塔、流量计、尾气监测单元组成.生物滴滤塔采用有机玻璃制造,有效高度为950 mm,塔内装填8 mm×10 mm,比表面积为1 200 m2/m3的PVC圆柱体生物填料,装填量共4层,每层层高100 mm,滴滤塔底部为储液槽.本系统采用逆流式操作,由转子流量计控制其喷淋量,试验装置见图 2.

-

培养基配制方案:

将0.1 g FeSO4·7H2O,0.04 g ZnSO4·7H2O,0.004 g CuSO4·5H2O,50.0 g (NH4)2SO4,0.02 g CaCl2·2H2O,2.0 g MgCl2·6H2O,0.008 g CoCl2·6H2O,0.002 g MnCl2·4H2O,0.004 g Na2MoM4·2H2O,32.0 g K2HPO4和16.0 g NaH2PO4·2H2O溶于蒸馏水中[15].

-

二甲苯的测定:采用Agilent 7890分析进气口和出气口二甲苯质量浓度,色谱柱采用Agilent HP-Innowax毛细血管柱(30 m×0.32 mm×0.5 μm)进样口、检测器(FID)、柱温分别为200,280,150 ℃,气体进样量为100 μL.

扫描电镜(SEM):由于生物滴滤塔选择的填料为不导电的PVC填料,因此在进行扫描电镜观察前需对样品进行喷金预处理.预先将填料裁剪为大小合适的小片,用导电胶粘在铜座上,通过离子溅射仪进行喷金,喷金后将铜座置于扫描电镜进行观察.

pH值:IS128C pH计(上海仪迈仪器科技有限公司).

1.1. 试验装置

1.2. 培养基

1.3. 分析方法

-

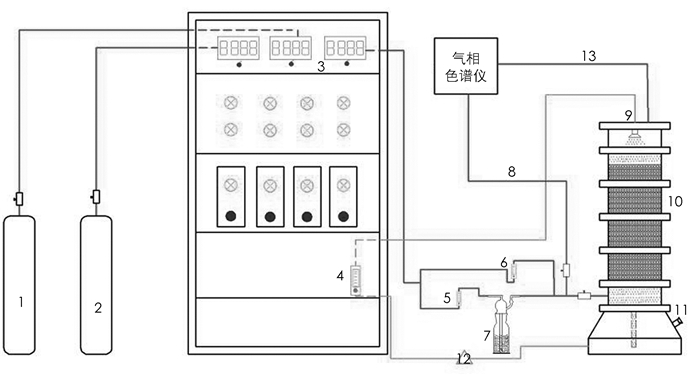

反应器启动时菌种来自实验室前期分离得到的不动杆菌属(Acinetobacter sp.).菌种在生物滴滤塔中的挂膜驯化通过配制喷淋液3 L并调节pH值至6.8~7.2,气体以O2流量200 mL/min、N2流量1.2 L/min、喷淋液流量20 L/h的条件每天连续运行8 h,每两天更换一次喷淋液.经30 d驯化培养,分别取上层和下层填料样品,通过扫描电镜观察微生物在填料上的生长情况(图 3).

由图 3可知,经30 d的运行,反应器内填料上均有明显的生物膜生长,下层填料的微生物生长更致密.其原因一方面是上层填料受到喷淋导致的水力冲刷作用,另一方面是反应器内微生物均为好氧微生物,氧气由滴滤塔下方通入,下层填料中微生物更易利用氧气维持生命活动.

-

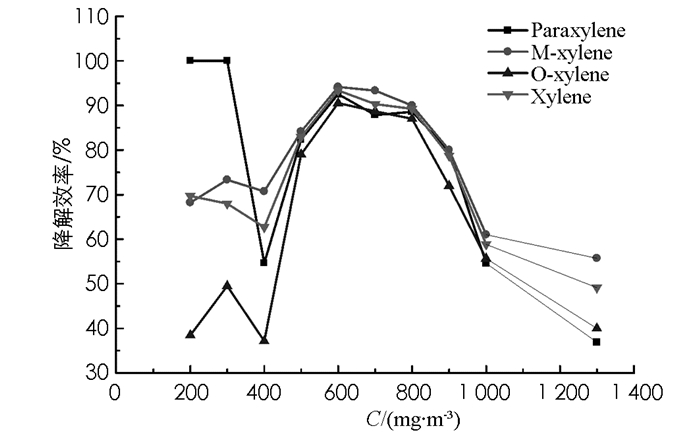

在二甲苯进气质量浓度由200 mg/m3升至1 300 mg/m3,滴滤塔气体流量为1 000 mL/m3,氧气体积分数为15%的条件下,此时气体停留时间为140 s,分析底物质量浓度对生物滴滤塔微生物降解二甲苯效率影响,结果见图 4.

由图 4可知,二甲苯邻、间、对3种同分异构体以及二甲苯总的降解效率随进气二甲苯质量浓度的提高呈先上升后下降的趋势.对于3种同分异构体而言,降解效果从强到弱依次为间二甲苯、对二甲苯、邻二甲苯,间二甲苯的降解效率最高.在低质量浓度(低于500 mg/m3)和高质量浓度(高于1 000 mg/m3)进气条件下,邻二甲苯的降解效果最差,此现象的出现是由于二甲苯3种同分异构体的取代基位置不同所导致[16-17].与张鹤清等关于微生物六种挥发性有机物性能研究结果一致[18]. Sun等人[19]的研究也发现了相似规律,二甲苯3种同分异构体中,邻二甲苯的生物降解性能最差.在进气质量浓度为600 mg/m3条件下,总二甲苯降解效率最高,二甲苯3种同分异构体以及总二甲苯的降解效率分别为92.54%,94.18%,90.53%和93.36%,因此,滴滤塔的最佳进口质量浓度为600 mg/m3.

-

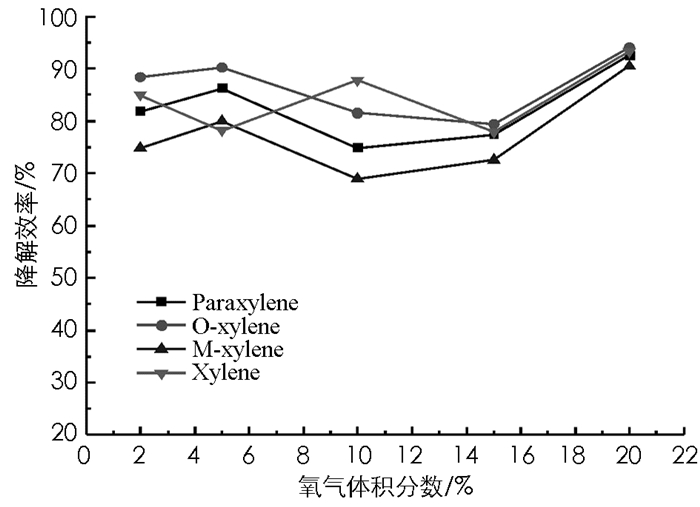

在氧气体积分数梯度为20%,15%,10%,5%,2%条件下,滴滤塔进气质量浓度为600 mg/m3,营养液喷淋量为20 L/h,氧气体积分数对滴滤塔降解二甲苯效果的影响见图 5.

由图 5可知,氧气体积分数在20%时,二甲苯3种同分异构体以及总二甲苯的降解效率,均可达到90%以上.当氧气体积分数降至2%,总二甲苯的降解效率仅下降为85%左右.其原因可能为,微生物的生长需要氧气,而循环液中的溶解氧量在进气中氧气体积分数为2%时,经分析检测也基本维持在3~4 mg/L.因此氧气体积分数对本体系二甲苯降解效率的影响不大.考虑到工业烟气中氧气体积分数通常在15%左右,因此本体系选取15%氧气体积分数作为最佳条件.

-

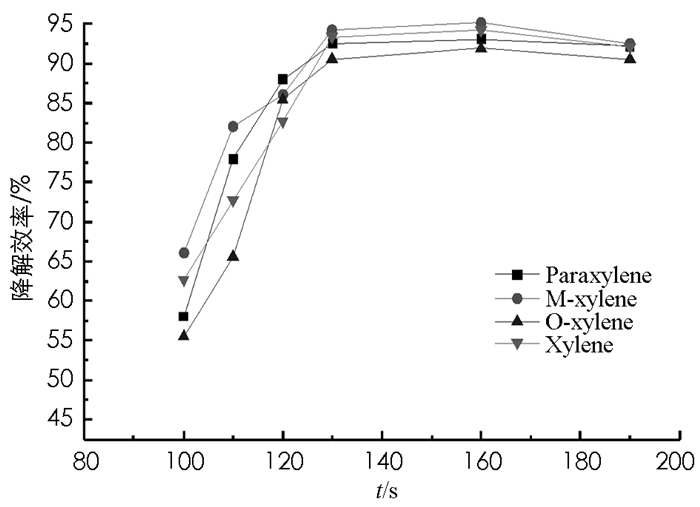

保持二甲苯进口质量浓度为600 mg/m3,氧气体积分数为15%,营养液喷淋量为20 L/h的条件不变,通过改变滴滤塔总进气量来改变气体停留时间(EBRT),在EBRT梯度分别为100,110,120,130,160,190 s考察滴滤塔的二甲苯降解效果,结果见图 6.

由图 6可知,二甲苯的3种同分异构体以及总二甲苯的降解效率随EBRT的增大而增大,3种同分异构体中,间二甲苯的降解效果最佳.当EBRT为100 s时,3种同分异构体以及总二甲苯的降解效率分别为56.0%,66.1%,55.5%,62.7%.当EBRT大于130 s时,二甲苯的3种同分异构体以及总二甲苯的降解效率基本维持在90%以上,降解效率达到最高.综合考虑成本问题,最佳EBRT为130 s.

2.1. 反应器启动阶段

2.2. 二甲苯进气质量浓度对微生物降解效率影响

2.3. 氧气浓度对二甲苯降解效率的影响

2.4. 气体停留时间(EBRT)对降解效率的影响

-

1) 采用实验室前期培育高效二甲苯降解菌不动杆菌属(Acinetobacter sp.)在生物滴滤塔中驯化挂膜以降解含二甲苯有机废气,通过SEM电镜分析,经过30 d驯化培养生物膜基本形成,并且滴滤塔下层填料微生物长势好于上层填料.

2) 稳定运行期间,系统最佳运行条件为:进口质量浓度600 mg/m3、EBRT130 s、氧气体积分数15%,此时生物滴滤塔降解效果最佳,对二甲苯及其同分异构体的降解效果可达90%以上,且二甲苯同分异构体之间的降解效果从好到差依次为:间二甲苯,对二甲苯,邻二甲苯.

DownLoad:

DownLoad: