-

天然橡胶树要获得较高的胶乳产量,其中一项重要工作就是通过先进的割胶机械来实现[1-2].割胶工作是一个劳动强度大、技术难度高的过程,在获得较高产量的同时,还要保证橡胶树的持续产胶能力,因此割胶人员必须具备良好的割胶技术[3-4].目前传统的人工割胶早已不能满足橡胶产业的发展需要,机器代替人工割胶是割胶行业发展的大方向.

近几年针对割胶机械自动化程度低开展了一些研究[5-7],如许振昆等[8-9]设计了一种全自动式割胶机及割胶方法,最大程度地解决了人工割胶劳动强度大、作业技术要求高以及人工割胶不够精细化等问题,但考虑到机械性能、割胶效果、成本等原因,仍无法在生产中大面积推广使用.李乔[10]发明了一种半自动割胶机,依靠触发点、传动杆和传感器可以实现端点检测、曲线行刀、自动换行、刀口深度可调等一系列动作,由于天然橡胶树干并非理想圆柱形,此机构对橡胶树的适应性比较差,仅依靠人工把持,支撑臂固定,装置稳定性不高.中国热带农业科学院橡胶研究所[11]设计了一种捆绑式自动割胶机,结构简单,便于制造及操作,有助于大幅度降低成本,但采用捆绑带进行固定,不能实现个人独立操作且操作相对繁琐.张俊雄等[12]开发了一种挠性仿形割胶装置,依靠仿形导向轮和装有磨粒的挠性带进行割胶,大大改善了对存在凸起或凹陷等缺陷的非理想橡胶树干的仿形效果,但是装置没有设置夹持机构,导向轮过多也增加了装置作业的不稳定性.

针对这些现状,本研究专门设计了一种可独立操作半自动轨道式割胶机,包括导轨装置、行走机构和切割装置.导轨装置是一个相对割胶路径平行设置的仿形机构,采用齿轮齿条方式传动,行走机构设置于轨道上,并能沿轨道在切割橡胶树皮的平面内移动,切割装置设置于行走机构上,用于切割橡胶树皮,并对相关重要机构进行了模态分析和载荷受力分析,为割胶机的进一步改进和设计提供了方法和依据.

全文HTML

-

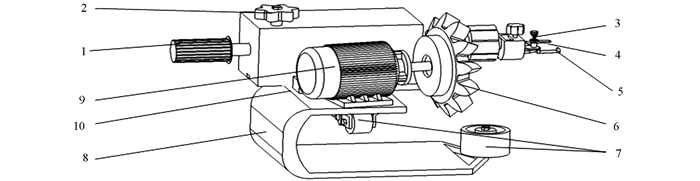

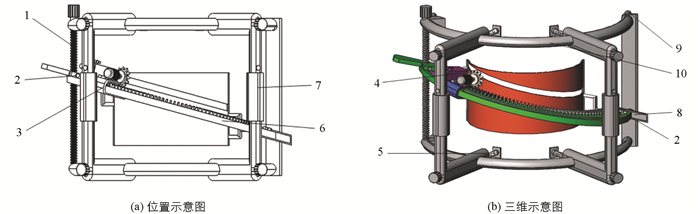

可独立操作半自动轨道式割胶机结构如图 1所示,主要由导轨角度调节丝杆、限位开关、切割装置、行走机构、抵触杆调节丝杆、导轨装置、把持机构、导轨角度调节滑块机构、支撑脚架和固定机架等组成.固定机架实现对整个机构重要部件位置的确定,并仿照橡胶树圆柱表面进行形状结构设计,左右把持机构呈径向60°布置于固定机架上.

割胶机的设计建立在个人独立操作基础上,导轨装置是一个相对于割胶路径平行设置的仿形机构,采用齿轮齿条方式传动,两边设置有限位机构;行走机构设置于轨道上并能沿轨道在切割橡胶树皮的平面内移动,包含电机、行走齿轮、导向轮;切割装置设置于行走机构上,包含刀具动力头、深度调节器.切割装置依靠轨道行刀进行割胶,避免了水平竖直合成运动带来的机构复杂性问题;行走结构采用齿轮齿条,增加了机构作业的稳定性,轨道进行了角度可调节设计;仿形机构依托割胶刀运行,设计了可实时调节的抵触杆,提高了运动轨迹的精度.

-

固定机架左端设计了可调节导轨装置角度的机构,同时在固定机架右端支撑杆设计了旋转滑块机构以调节导轨装置角度.导轨装置安装在左端角度调节机构和右端支撑杆之间,分别在左右两端设计了行走机构限位装置.行走机构采用齿轮齿条方式工作,设计了3个导轨装置行走导向轮,在行走机构上设计了切割装置,切割装置主要包括切割刀、切割刀调节装置、仿形轮,再搭配一个微型的发动机提供行走机构的动力.

机构的工作过程:工作前对切割对象橡胶树进行大致的估算,初步确定割胶刀切割橡胶树的深度,利用位于割胶刀上方的锁紧螺钉进行锁紧.根据橡胶树已有割线,通过右端螺纹丝杆手动调节导轨装置的角度,以适应不同橡胶树最佳割胶位置.利用电机控制系统,按下启动按钮启动微型电机,电机回到切割初始位置,触碰限位机构开关立即停止,准备进行第一轮割胶.工作人员左右手握住圆柱形把持机构,依靠左右把持机构上下端的螺纹丝杆调节装置,实现整个机构与橡胶树表面的最佳贴合.观察割胶刀切入橡胶树皮的位置是否合理,手动调节切割装置末端的割胶刀深度调节杆到最佳位置,割胶准备工作到此完成.启动电机控制系统,微型电机带动前头齿轮正转(顺时针),齿轮与导轨齿条配合,开始在导轨上行走,切割装置依托行走机构开始对橡胶树进行切割,切割动作执行到导轨下端时,触碰限位机构开关,割胶机停止工作,手动控制割胶刀深度调节杆,缩回割胶刀,启动微型电机开关,实现齿轮反转(逆时针),回到导轨上端初始位置触碰限位机构开关,电动机立即停止,整个割胶过程完成.

1.1. 整机结构

1.2. 工作原理

-

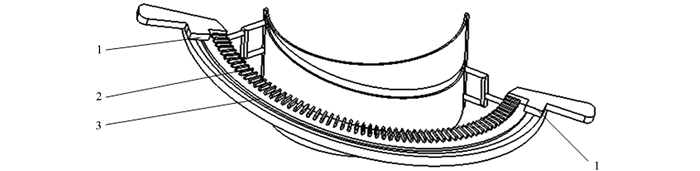

导轨装置结构如图 2所示,导轨装置是一条左右固定并有一定曲率的齿条,齿条外缘平行于齿条设计了行走轮轨道,分别在左右两端设计了1个行走机构限位装置(考虑零件装配,其中省略).

-

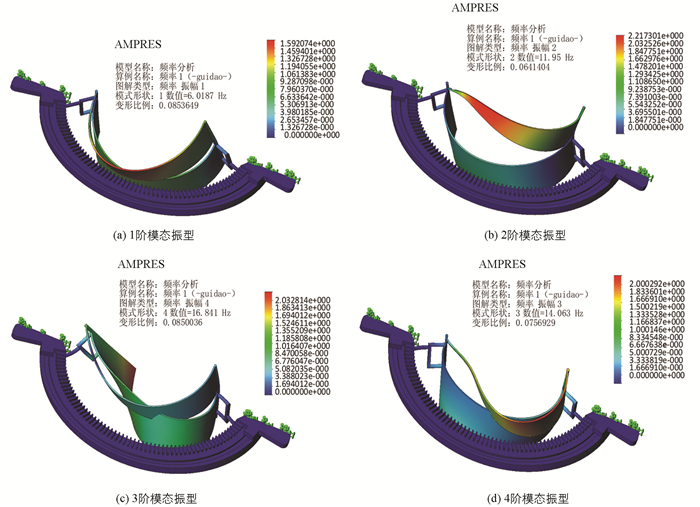

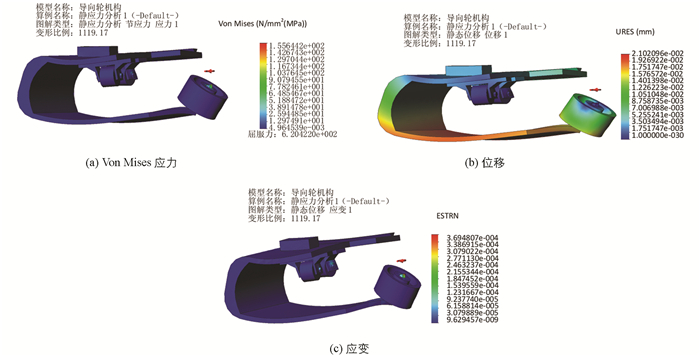

导轨装置是整个机构的重要部分,为了保证行走机构在割胶时的稳定性,本研究采用Solidworks simulation软件,对导轨装置进行了有限元分析.为分析割胶全过程中导轨上行走机构(包括其上的割胶装置)的震动情况,防止整个机构产生共振,对其进行模态频率分析.导轨装置在频率计算时不考虑载荷,只承受行走机构(包括其上的割胶装置)的自重50 N,配置质量为6.81 kg,体积为5 234.72 cm3,密度为1.30×103 kg/m3,重量为66.69 N,分析频数设置为5阶,关闭软弹簧,零应变温度为298 K,关闭液压效应.

添加材料属性,模型属性设置为PVP僵硬,模型类型为线性弹性同向性,张力强度为40.70 MPa,质量密度为1.30×103g/cm3,弹性模量为2410 MPa,泊松比为0.38.网格类型选为实体,设置雅克比点为4点,最大单元大小为38.75mm,最小单元大小为7.75mm,选用基于曲率的高品质网格进行划分,节点总数为34249,最大高宽比例为479.88.根据结构的实际工作状况,考虑到割胶机在工作时通过导轨装置移动切割,在左右两端的导轨装置与固定机架接触点添加固定边界条件,计算得出导轨装置模态分析结果,如图 3所示.

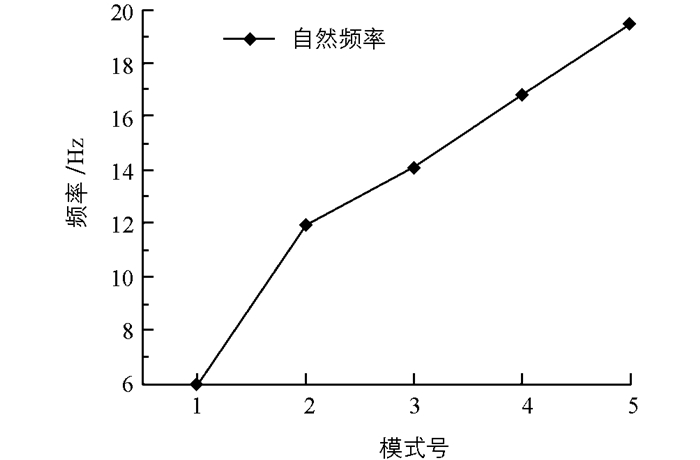

由图 3可知,振动变形主要发生在抵触杆与橡胶树表皮接触位置,且随着频数的增加,导轨内侧固定的橡胶树表皮变形程度越来越大,行走机构始终保持稳定.为了加快计算速度,只设置了5个模式进行频率分析,如图 4所示.随着自然频率的增大,周期不断减小,可以看出在模式号2(频率达到11.95 Hz)过后,自然频率成线性增加,斜率基本不再变化,模式号继续增加对频率已经没有较大波动影响,因此导轨装置在小振幅和低阶模态频率时不会与行走机构产生共振.

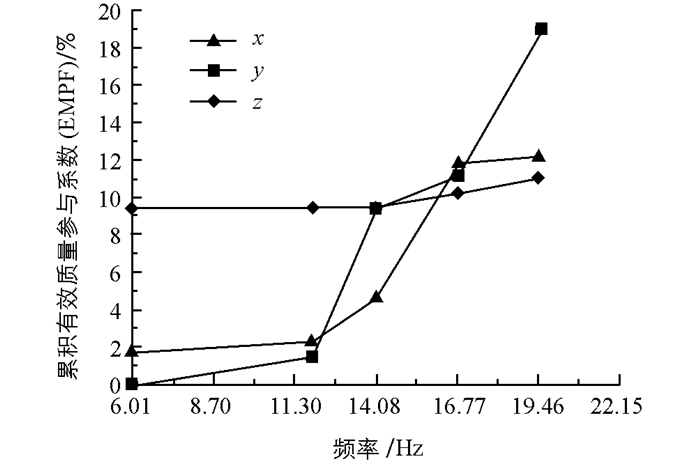

建立频率响应图表,累积有效质量参与系数,如图 5所示.从图中可以看出,累积有效质量参与在x,y,z方向呈上升趋势,在模式号3(频率达到14.06 Hz)以后基本趋于稳定上升,说明累积有效质量参与将不随频率线性增加而发生明显波动,行走机构与导轨装置将不会产生共振.

-

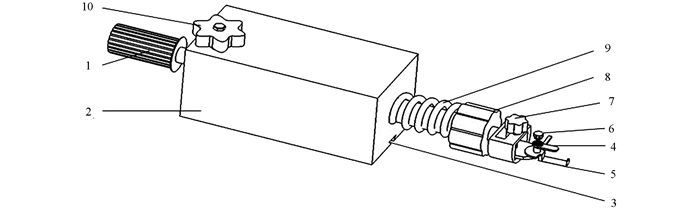

行走机构包含行走架、微型电机、电机控制系统等,如图 6所示.行走架支撑起整个机构,依靠3个行走导向轮在导轨装置上移动,其中2个较小的导向轮布置在导轨装置上方,1个较大的导向轮布置在导轨装置内壁,构成三角形稳定行走机构.微型电机依靠电机系统控制齿轮的正反转,切割装置固定于行走机构上,并对橡胶树进行切割.

-

行走机构是靠齿轮与导轨啮合工作的,行走架和导向轮是其核心部件,其性能直接影响割胶效果,考虑到行走机构稳定性,对行走架和导向轮进行静力分析.打开热力效果,设置298K为零应变温度,配置材质属性为合金钢,失败准则设定为最大von Mises应力,屈服强度为620.42 MPa,张力强度为723.83 MPa,弹性模量为2.10×105 MPa,泊松比为0.28[13],质量密度为7.70×103 g/cm3,抗剪模量为7.90×104 MPa,热扩张系数为1.30×10-5/K.在行走架底面添加固定边界条件,在导轨装置内壁行走轮上加载离心力,角速度为50 rad/s,角加速度为0 rad/s2.网格类型选为实体,设置雅可比点为4点,最大单元大小为12.17 mm,最小单元大小为2.43 mm,选用基于曲率的高品质网格进行划分,节点总数为10 539,单元总数为5 703,最大宽度比例为16.18,没有扭曲单元,计算得出应力、应变和位移分析比较结果,如图 7所示.

由图 7可知,行走架和导向轮的Von Mises应力没有达到屈服极限应力值620MPa,同时行走机构也没有出现明显的应力和应变集中,但导轨内壁的导向轮发生了较大的位移变形,这是由于割胶刀作用于橡胶树表面的径向正压力可以直接传递到导向轮所导致的,说明导轨装置内壁与导向轮接触部分是行走机构稳定性最差的地方,在实际加工行走机构时,要对此部分进行加固处理.

-

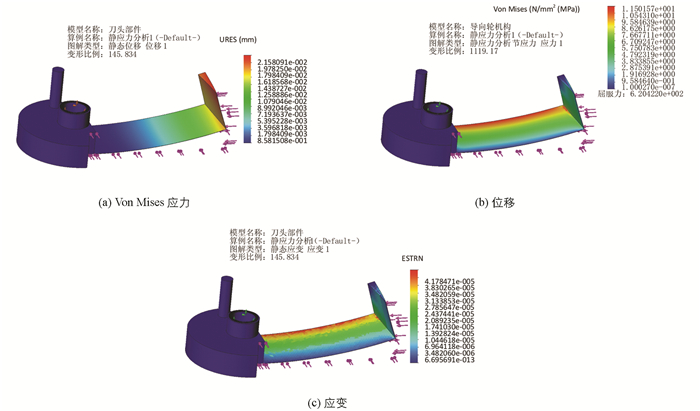

切割装置包括割胶刀机构、割胶刀控制机构、仿形机构、割胶刀压紧机构等,如图 8所示.割胶刀部分包括L型割刀、抵触杆.为了增大切割时散热面积,并对已切割橡胶树皮进行导流,L型割胶刀角度设计成90°,为了有效减小割胶阻力,割刀面面宽设计成1 mm,抵触杆位于割刀上方,对割刀进行限位并控制切割深度.仿形机构位于割刀下方,对不规则橡胶树进行仿形,压紧装置位于割刀后方,实现抵触杆与橡胶树表皮贴合.割胶刀控制机构位于最后方,可手动调节割刀切割深度,进行不同橡胶树切割.

-

切割装置性能决定了整个割胶机切割能力,对割胶刀的性能作静应力分析,为简化机构,减少运算量,只对刀头部件进行有限元分析.配置材料属性为合金钢,屈服强度为620.42 MPa,张力强度为723.83 MPa,弹性模量为2.10×104 MPa,泊松比为0.28[13].模拟割胶过程中刀片实际受力情况,在L型割胶刀的两个切割面分别添加1kN正压力和1kN切向力,在刀座安装孔的内圆柱面上添加固定约束.网格类型选为实体,设置雅可比点为4点,最大单元大小为0.35 mm,最小单元大小为0.12 mm,采用基于曲率的最高品质网格进行划分,节点总数为112 517,单元总数为72 375,最大高宽比例为23.78,没有扭曲单元,有限元分析结果如图 9所示.

由图 9可知,L型割胶刀上表面的Von Mises应力、应变沿切向力方向递增,位移变形量始终保持不变,说明切割时,割胶刀受橡胶树皮阻力作用,会产生一个相对固定螺钉向后逐渐增大的拉扯力,而不会引起割胶刀位移的变化;L型割胶刀与橡胶树皮相平行的2个面上产生了最大位移变形,Von Mises应力在屈服应力以内,说明割胶时,橡胶树皮对割胶刀的正压力在导致割胶刀变形的同时却不会产生过大的应力集中,这可以为进一步设计和分析L型割胶刀角度、割面宽度,优化割胶刀性能提供了理论依据.

2.1. 导轨装置结构设计及分析

2.1.1. 导轨装置结构

2.1.2. 导轨装置分析结果

2.2. 行走机构设计及分析

2.2.1. 行走机构设计

2.2.2. 行走机构分析结果

2.3. 切割装置设计及分析

2.3.1. 切割装置设计

2.3.2. 切割装置分析结果

-

1) 针对目前全自动割胶机普遍存在价格昂贵、机械性能、割胶效果不理想、作业的不稳定性大、不能实现个人独立操作且操作相对繁琐、机构对橡胶树的适应性比较差等特点,本文研制了可独立操作的半自动轨道式割胶机,整机采用人工可独立把持、轨道式自动割胶,可降低割胶的劳动强度和技术难度,提高割胶机的适应性,可有效降低割胶成本,实现个人独立割胶.

2) 对整个机械主要机构、装置进行了全面分析,阐述了多个机构之间协同工作的特点,对整个机构以及各部分装置的工作原理进行了分析.

3) 通过对关键零部件的模态分析和应力、应变、位移分析,研究确定了该机械在工作过程可能出现的最大影响因素,为割胶机的进一步研究发展提供了理论依据.

下载:

下载: