-

我国是世界第一烟草种植大国,种植面积在100万hm2左右,占世界产量的35%.烟草是我国重要的农业经济作物,并且是忌连作的农作物[1-3].传统的烟杆根系去除作业(特别是丘陵山区)主要是靠人工手拔、锄头挖根等方式进行,费时费力,效率也不高,工作量大,人工成本高[4],残留的根系腐烂后也会破环土壤养分平衡,改变土壤微生物多样性,导致烟草生长不良,产量和品质下降[5-6].所以亟需有关烟兜根系去除机械设备来帮助提高效率、降低劳动强度和人工成本.

目前,国外现有的拔杆机械的作业方式大多属于破坏性拔杆,即将茎杆直接粉碎还田,配套动力大多采用中小型拖拉机,体积结构较大,大多无法适应小地块烟田的作业环境[7];我国针对烟杆作物的研究起步相对较晚,国内现有投入生产和使用的烟杆挖掘机械设备还比较少,且大多数采用中小型拖拉机作为配套动力,底盘笨重,大多数在一些平原地区推广,适应南方山地丘陵地带小地块烟田的机械设备还比较欠缺[8].由于受我国烟草作物种植制度的限制,拔杆机械设备必须能够将烟杆连同根茎一起拔除并清理出田,以满足次年的烟草的种植要求.因此针对南方丘陵山区特点,烟草拔杆去根机械设备必须朝小型轻便化的方向发展.基于以上要求,本文研制了一种小型轻便的烟兜挖掘装置,针对其挖掘机构进行了运动学分析和整机田间试验,研究结果可为完善根茎挖掘机的结构设计和作业参数优化提供参考.

全文HTML

-

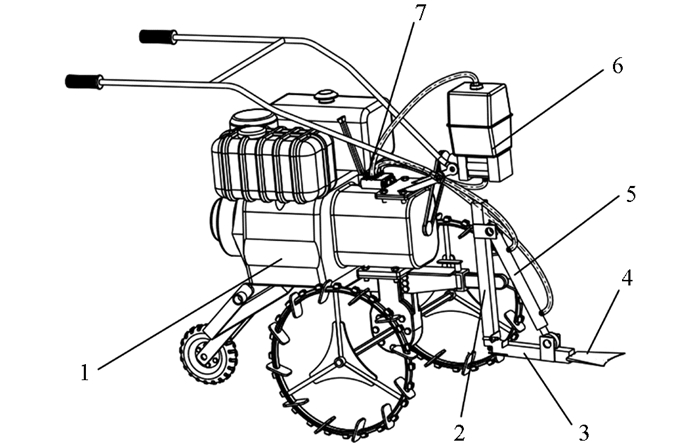

我国烟草种植规模差异较大,国内所起的烟垄垄体一般呈三角形或抛物线型,南方烟草种植区的种植行距一般1 200 mm,垄高为300 mm,垄底宽为900 mm,株距为500 mm;主要根系分布一般在茎基周围18 cm,深25 cm的土层内[4],如图 1所示.

-

烟兜挖掘装置以微耕机为动力平台(提供前进的动力),液压泵站作为动力源(提供机构姿态变化的动力).如图 2所示,具体工作原理为:将烟兜挖掘机构及液压泵站装配在微耕机上,整机前进,当微耕机行驶至合适位置时,拉下手动阀的伸长换向杆,液压缸活塞杆伸出,挖掘铲入土,达到深度后,松开伸长换向杆,此时液压缸活塞杆保持静止.微耕机再前进一段距离后,拉下手动阀的收回换向杆,液压缸活塞杆收回,液压缸回到初始状态,松开收回换向杆,完成整个烟兜挖掘作业.

1.1. 整机结构及主要技术要求

1.2. 工作原理

-

为了研究挖掘机构的运动学性能,并为其力学分析、优化设计以及虚拟样机仿真提供理论基础,需要对该机构建立运动学模型并进行相应的运动学分析.本文主要采用坐标法对该机构运动的每个过程进行运动学建模,列出液压缸活塞杆的伸出、保持、收回过程并进行相应的运动学分析,求解工作空间,对该机构的各个运动状态进行数学描述,最后求解出各个工作状态空间的速度以及他们之间的关系[9].

-

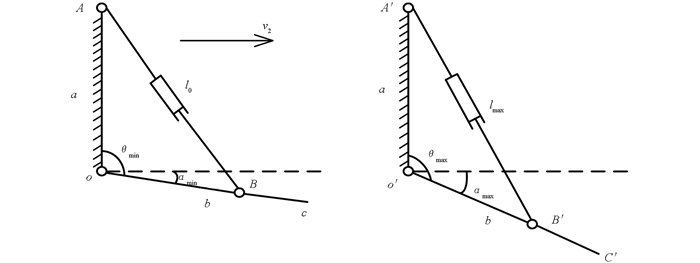

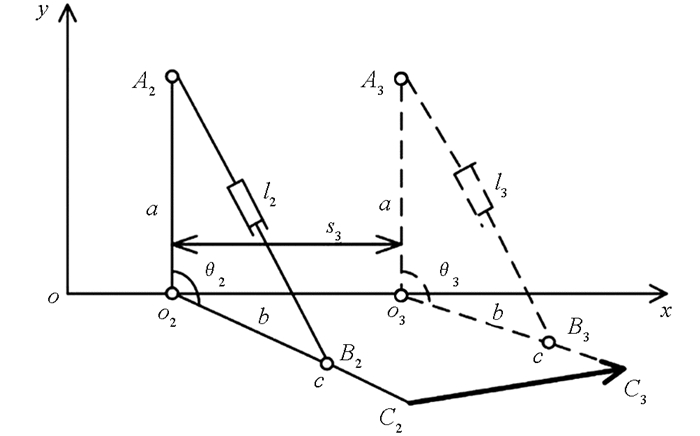

液压缸活塞杆的伸出和收回会引起转动杆关节空间转角的变化,建立运动空间简图,如图 3所示,OA为固定臂,OB为转动臂,BC为挖掘铲,v2为微耕机前进速度方向.

由图 3可得,根据余弦定理有

式中:θ为转动杆OB与固定臂OA的夹角,°;α为转动臂OB与前进速度的夹角,°;a为固定臂OA的长度,mm;b为转动杆OB的长度,mm;l0为液压缸伸出的长度,mm.由此可得

将液压缸最大伸长长度lmax代入式(1),可得

因此转动杆关节的转角范围为

-

以挖掘铲为研究对象,通过挖掘铲中心点的位置坐标[x,y]以及挖掘铲的姿态角α(挖掘铲参考点C与转动点O的连线与前进方向的夹角)可以唯一确定挖掘铲的空间状态,利用矢量[x,y,α]T表示.

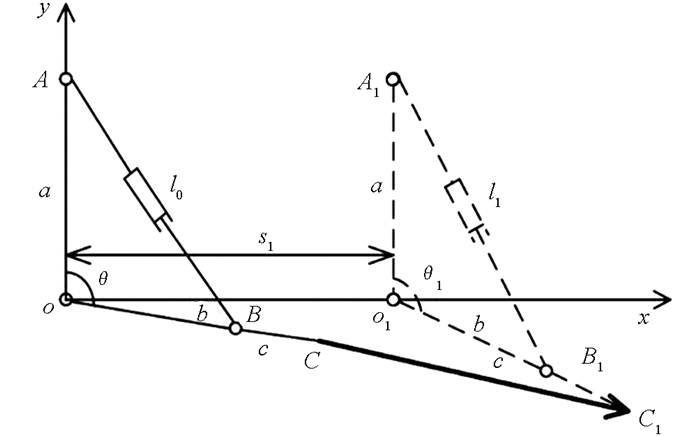

1) 液压缸伸出状态

在液压缸伸出的过程中,为了便于研究,假设液压缸活塞杆直线往复运动速度和微耕机前进速度是恒定的,分别为v1和v2.如图 4所示,将大地视为定坐标系XOY,将该机构视为动坐标系(以转动点O为坐标原点,微耕机前进方向为x轴,与前进速度垂直的方向为y轴),因此,在该空间中挖掘铲参考点的位移矢量为CC1,参考点位置C1坐标可以表示为

式中:s1表示在伸出工作空间该机构前进的距离,mm;c表示挖掘铲参考点到转动点O的距离,mm;θ1表示该空间任意状态下转动臂OB与固定臂OA的夹角,°,计算表达式为

式中:l1表示在该空间任意状态液压缸的总长,mm.

因此,挖掘铲在伸出阶段的姿态空间状态可以表示为

其中,s1=v2t1,l1=l0+v1t1,

${\sin {\theta _1} = \sqrt {1 - {{\left( {\cos {\theta _1}} \right)}^2}} }$ ,t1表示保持阶段的总时间,s.2) 液压缸保持状态

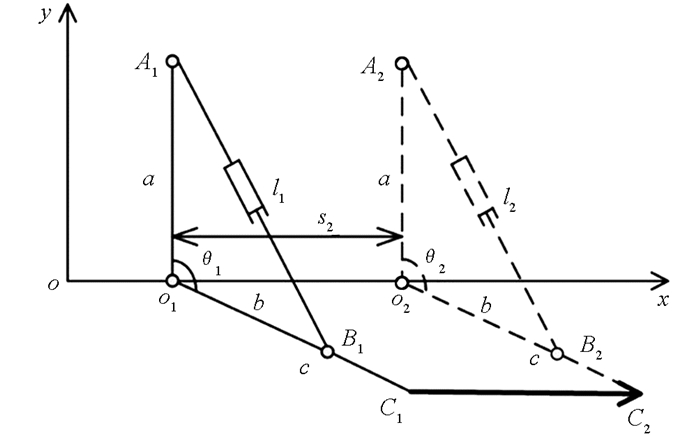

同理,可得挖掘铲参考点在该空间的位移矢量C1C2,如图 5,参考点的位置坐标C2可表示为

式中:s2表示在保持工作空间该机构前进的距离,mm;θ2表示该空间任意状态下转动臂OB与固定臂OA的夹角,计算表达式为

式中:l2表示在该空间任意状态液压缸的总长,mm.

因此,挖掘铲在液压缸保持阶段的姿态空间状态可以表示为

其中,s2=v2t2,l2=l0+v1t2,

${\sin {\theta _2} = \sqrt {1 - {{\left( {\cos {\theta _2}} \right)}^2}} }$ ,t2表示保持阶段的总时间,s.3) 液压缸收回状态

同理,可得挖掘铲参考点在该空间的位移矢量C2C3,如图 6,参考点的位置坐标可表示为

式中:s3表示在保持工作空间该机构前进的距离,mm;θ3表示该空间任意状态下转动臂OB与固定臂OA的夹角,°,计算表达式为

式中:l3表示在该空间任意状态液压缸的总长,mm.

因此,挖掘铲在液压缸收回阶段的姿态空间状态可以表示为

其中s3=v2t3,l3=l2-v1t3,

${\sin {\theta _3} = \sqrt {1 - {{\left( {\cos {\theta _3}} \right)}^2}} }$ ,t3表示保持阶段的总时间,s.

2.1. 烟兜挖掘机构运动空间模型建立

2.2. 烟兜挖掘机构姿态空间

-

由烟兜挖掘装置姿态空间状态可知,挖掘铲的挖掘深度h(即y坐标)主要与θ有关,而θ的变化主要由液压缸的伸出量变化引起.又因为液压缸活塞杆伸长量Δl=v1t,因此挖掘深度h与活塞杆伸出速度v1的关系为(忽略液压缸安装点分别距固定臂和转动杆的尺寸)

式中,a=700 mm,b=260 mm,c=540 mm,l0=600 mm.

Adams是一款虚拟样机分析软件,在运动学领域应用极其广泛.烟兜挖掘装置(简化)通过Creo3.0建模后导入Adams中,如图 7所示.

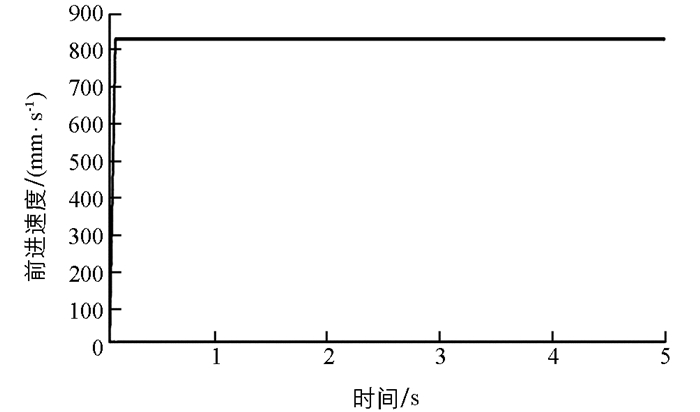

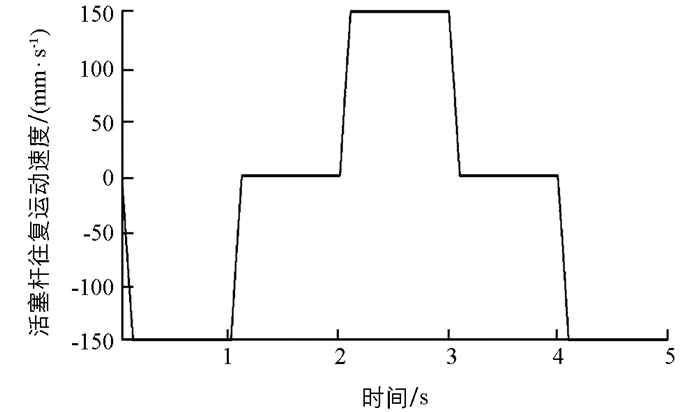

1) 定义液压缸缸筒在固定臂上的转动副以及活塞杆在转动杆上的转动副[10],定义固定臂与地面之间的移动副并创建驱动,定义速度为833 mm/s(即整机前进速度为3 km/h),同时定义液压缸缸筒与活塞杆之间移动副并创建驱动,定义其活塞杆往复运动速度为150 mm/s,如图 8、图 9所示.

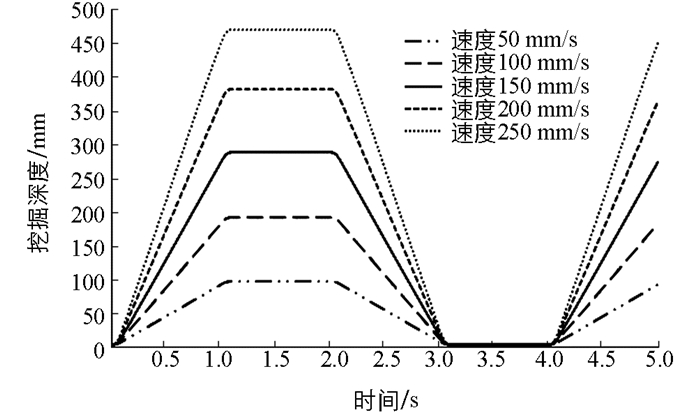

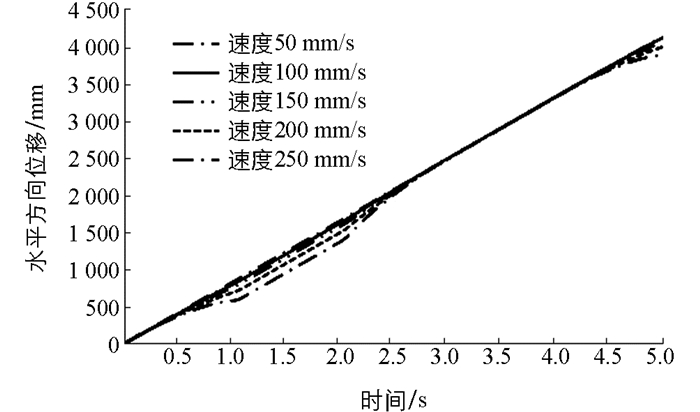

2) Adams仿真试验的目的是为了更加直观地观察挖掘铲的水平位移,挖掘深度(竖直位移)与时间的关系.在挖掘铲上创建其参考点,在指定的前进速度下,设置液压缸活塞杆不同的伸出速度进行运动仿真[11].仿真结束后,得到的结果如图 10、图 11所示.

如图 10所示,在前进速度一定的条件下,在同一个周期(挖掘一株烟兜的时间)内,挖掘深度随液压缸活塞杆伸出速度的增大而增大.如图 11所示,同理,在0.5~2.7 s内有明显的差异,主要是由挖掘铲不同转动速度在前进方向上的速度分量的不同造成,但在一个周期内,挖掘铲的水平位移量与液压缸活塞杆往复运动速度无明显关系.

-

为了进一步检验烟兜挖掘装置的性能,按照上述设计的模型图及相关参数,设计了一种烟兜挖掘装置[12],如图 12所示.试验地为重庆市北碚区缙云山西南大学烟草种植实践基地,试验地区土壤质地为黄壤土,土壤紧实度、土壤容重和土壤含水率分别为87PSI、0.99 g/cm3和32%.试验仪器主要包括微耕机(重庆鼎工1WG6.3-110FC-Z,已部分改装)、液压泵站(306右旋油泵动力机:额定压力16 MPa,工作转速800~2 000 r/min,油箱容积3.5 L)、HSG40液压缸(行程:500 mm,压力:16 MPa)、ZS-L118E-YT二联手动换向阀、4根高压油管、皮尺(量程:30 m)、卷尺(量程:5 m)、秒表.

-

选取烟叶收获后的长20 m、宽15 m的试验地块,将液压泵站及烟兜挖掘机构安装在微耕机上,利用秒表记录微耕机(液压泵不工作)前进10 m的时间,2次试验,计算得出微耕机前进速度为0.93 m/s.同理,利用卷尺和秒表测量出液压缸活塞杆伸出速度为86 mm/s.

-

试验的目的主要是检验该装置能否达到仿真预测的深度. 表 1为前进速度0.93 m/s、往复运动速度86 mm/s时的5次挖掘试验田间结果,田间试验结果同仿真预测值误差在7%~12%内.分析认为误差存在的原因:①田间土壤情况比较复杂,如存在细铁丝、碎石块、碎秸秆等增大了挖掘阻力,由于土壤—刀具间作用力比较复杂,仿真中未考虑阻力等因素;②同仿真相比,田间地表平整度对挖掘深度测量也产生了一定的影响.总体而言,田间试验实测结果与运动仿真结果基本一致.

4.1. 试验的目的及条件

4.2. 试验方法

4.3. 试验结果及分析

-

本文以微耕机为动力平台(提供前进的动力),结合液压系统设计了一种适用于丘陵山区的烟兜挖掘装置,根据结构特点依照其运动机理进行了运动学理论分析和仿真分析,结合液压缸活塞杆伸长量与伸出速度的关系(Δl=v1t),分析得出了在前进速度及伸出时间、保持时间、收回时间一定的情况下,挖掘铲的挖掘深度(竖直位移)随液压缸活塞杆伸出速度的增大而增大,挖掘铲的水平位移与活塞杆往复运动速度无明显关系.为了验证理论、仿真分析的正确性和检验该装置挖掘性能,进行了田间试验,实测数据表明在前进速度为0.93 m/s,活塞杆往复运动速度为86 mm/s时,挖掘深度范围为149~186 mm,与仿真预测结果相比,误差在7%~12%之内,对比结果表明了运动学理论分析和仿真分析的正确性以及该烟兜挖掘装置能够满足烟兜挖掘要求.

下载:

下载: