-

开放科学(资源服务)标志码(OSID):

-

我国丘陵山区耕地面积占全国总耕地面积的63.2%,其地块狭小零碎分散,缺乏机耕道,目前不适宜大中型农业机械耕作,所以微型农业机械在丘陵山区农业作业环节有着不可替代的作用[1-2]. 其中电动微耕机有体积小、结构简单、转移方便、耕作环节零排放等优点,尤其在农业机械向电动化发展的趋势下,对电动微耕机的研究非常有意义[3-5].

电动微耕机作业时随着耕作深度增加整机振动也更强烈,研究表明,在耕深大于10 cm的情况下每天使用4 h,3年后有10%的操作者出现白指病[6-10],但是在作业过程中耕深大于10 cm是非常必要的,因此如何在满足耕深条件下通过对整机进行减振保护操作者的身体健康,是电动微耕机在丘陵山区广泛应用的一个关键因素[11-12].

本文主要研究对象为一台自主研发的耕深大于10 cm的锂电池组电动微耕机样机在快挡作业情况下的竖直方向振动特性,电动微耕机扶手架处的振动直接影响操作者的身体健康,故而针对如何降低扶手架处振动的问题进行研究.

全文HTML

-

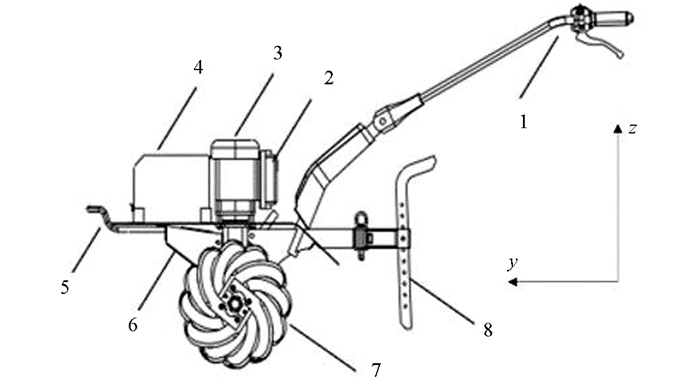

试验设备为团队自主研发的锂电池组电动微耕机样机(以下简称电动微耕机),其电池组由170枚比克公司生产的H18650CC锂离子单体电池,通过10组由17个单体电池串联而成的电池串并联而成,上下层分别呈7行10列和10行10列排列. 电动微耕机整机结构简图如图 1所示(z方向为电动微耕机作业时的竖直向上方向,y方向为前进方向),主要由扶手架、电机控制器、电动机、锂电池组、支撑架、行走箱、刀辊、限深杆组成. 扶手架上布置有刹车装置和控制旋钮开关,当锂电池组(位于发动机前)处于接通状态时,锂电池组为电动机供电. 刀辊既是耕作部件,也是行走部件,刀辊切削土壤时,土壤反作用力推动机组前进. 行走箱连接、支撑各个部件并与刀辊轴之间有力的传递. 末端支架设计有扶手架、限深装置连接结构,限深杆用于调节耕深. 电动微耕机设置有快档和慢档两个档位,快档转速较高,是电动微耕机的耕作档位,慢档转速较低,主要在转向的时候使用,其主要性能参数如表 1所示.

试验的仪器包括美国国家半导体公司生产的356A16型三向加速度传感器,该传感器使用频率范围为0.3~6 kHz,量程为±50 g,使用温度范围为-54 ℃~+80 ℃,传感器质量为7.4 g,x,y,x方向灵敏度分别为96.1,98.6,100.4 mV/g;美国国家仪器有限公司生产的NI9234数据采集卡,数据采集卡和传感器如图 2所示.

-

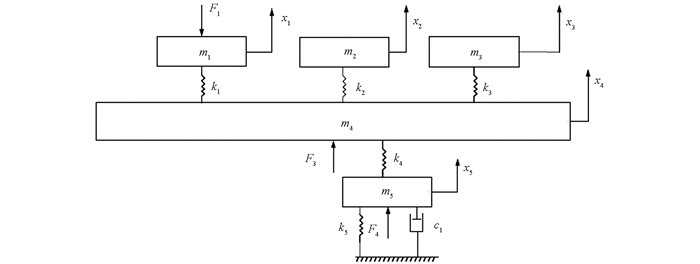

电动微耕机的振动由电磁激振力、刀辊切削土壤反作用力、被切土垡撞击挡泥板作用力、行走箱机械传动内力等几部分组成,电磁激振力、刀辊切削土壤反作用力、被切土垡撞击挡泥板作用力是电动微耕机主要的振动来源,针对主要振动来源对电动微耕机模型进行简化,将系统各模型部分动力作用过程进行组合得到系统竖直方向动力学模型,如图 3所示.

m1为扶手架的质量,m2为电动机质量,m3为锂电池组电池箱质量,m4为支撑架质量,m5为刀辊质量;x1为扶手架位移随时间变化函数,x2为电动机位移随时间变化函数,x3为电池箱位移随时间变化函数;x4为支撑架竖直方向振动位移随时间变化函数,x5为旋转刀辊竖直方向振动位移随时间变化函数;k1为扶手架与支撑架之间的刚度,k2为电动机与支撑架之间的刚度,k3为电池箱与支撑架之间的刚度,k4为刀辊与支撑架之间的刚度,k5为土壤的等效刚度;c1为土壤等效阻尼系数.

F1为扶手架处作用力,F3为土垡撞击力,F4为土壤对刀辊作用力.

根据图 3,可建立电动微耕机竖直方向一维振动系统微分方程为

电动微耕机扶手架处的振动直接影响操作者身体健康,所以需要减轻扶手架处振动,但是一旦优化扶手架结构就会导致整机质量发生变化从而影响耕深这一必要因素,在整机中支撑架相比于其他部件结构简单易于优化,因此需要通过优化扶手架和支撑架的结构,使得整机质量不变的前提下,实现对扶手架处的减振.

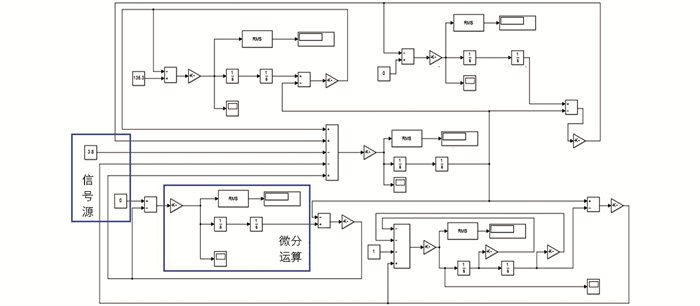

根据上述分析和公式(1),在matlab/simulink模块中将各个零部件的程序框图依次连接,并添加输出端为扶手架和支撑架,可以得到仿真程序图,如图 4所示.

-

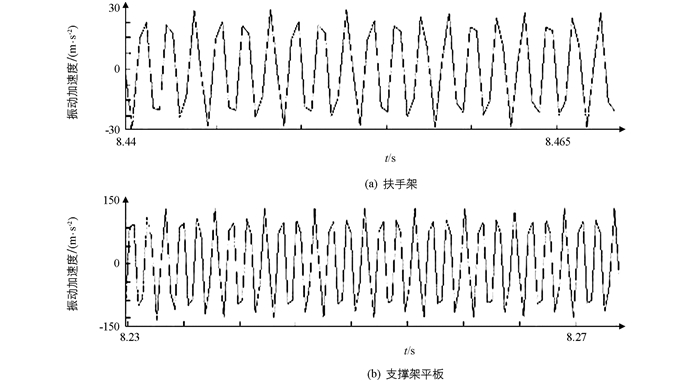

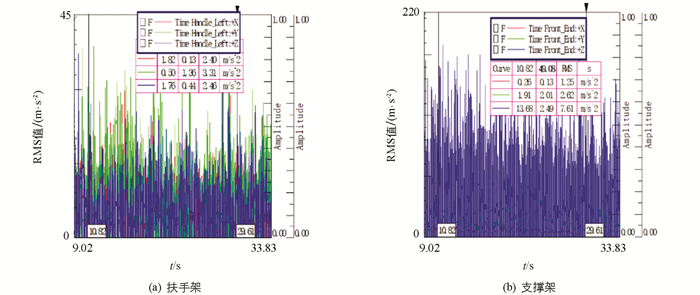

完成仿真参数的设置开始运行仿真,可以得出输出端支撑架平板与扶手架的竖直方向振动信号图,如图 5所示.

图中曲线表明,旋耕刀具入土时,表现为振动加速度增大,当刀具切削土垡向上运动时,振动加速度减小,因此刀具循环入土、出土环节中,振动加速度曲线与正弦信号类似. 运算结果显示,扶手架、支撑架平板处振动加速度均方根值(以下简称RMS值)分别为10.06,35.61 m/s2,其中人手连接的扶手架处的RMS值为研究的重点,是反映操作者健康状况的重要参数来源.

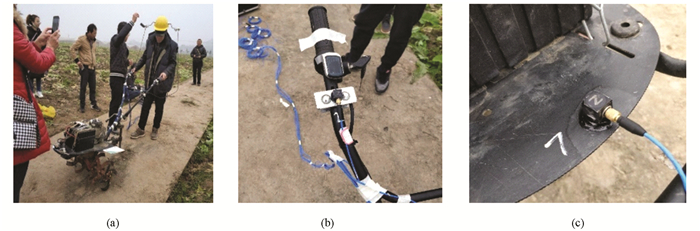

田间试验在重庆市合川区试验田开展,如图 6所示,该试验田位于106°23′45″E,29°39′45″N,田宽为35 m,长度为50 m,该试验田土地含水率为21%,土壤0~150 mm平均坚实度为0.453 MPa.

田间试验时将三向加速度传感器安装在电动微耕机的扶手架与支撑架上,将检测到的振动信号经数据采集卡传递至LabVIEW SignalExpress软件系统,得到扶手架与支撑架的振动加速度的时域变化波形,通过对时域特征值分析获得测点的振动加速度均方根值. 电动微耕机在基于快挡工况下进行耕作土壤试验,测试扶手架和支撑架平板处的振动曲线,整机接线布局与传感器布点图如图 7所示.

田间试验测得的电动微耕机扶手架和支撑架两处测点竖直方向振动加速度时域信号滤波处理如图 8所示,可以得到扶手架、支撑架平板处RMS值分别为10.45,49.08 m/s2.

-

将仿真与试验结果进行对比,如表 2中数据分析可知,仿真误差主要源于动力模型简化中没有考虑部件阻尼系数、限深杆处作用力等振动参数以及田间振动试验中的测试误差. 对于机械振动特性仿真,一般要求仿真与实验误差小于20%[13],因此本次仿真与实验误差满足精度要求,该模型可以进行重复利用.

1.1. 试验设备与仪器

1.2. 模型建立

1.3. 仿真与试验

1.4. 结果对比

-

为了尽量减缓操作者得白指病,一般扶手架处z轴方向振动RMS值不超过10 m/s2,而且z轴振动RMS值应该尽可能减小[14],但是前文仿真与试验的扶手架处RMS值均超过10 m/s2,所以需要对电动微耕机进行减振,根据前文所述,应对支撑架和扶手架进行结构优化从而实现扶手架处振动减小.

结构优化又分为尺寸优化、形态优化以及拓扑优化,对于支撑架而言因为其与行走箱、电动机等相连接,所以无法进行尺寸优化,而且加工时又直接以整板形式与其他部件装配,所以可以对支撑架进行拓扑优化;对于扶手架而言,因为需要保证操作者在农作时最佳的舒适性,同时与支撑架连接的空心钢管壁厚已经固定,所以不能对扶手架进行尺寸优化和对整体进行形态优化,只能在局部进行形态优化和拓扑优化.

-

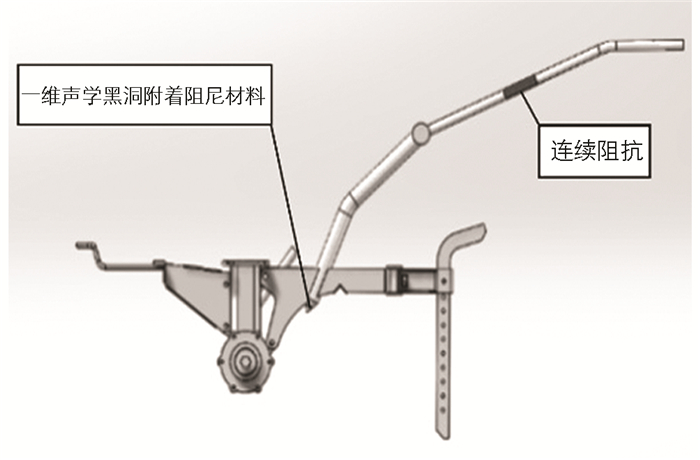

电动微耕机扶手架作为圆形杆件,通过采用单一引入渐变阻抗界面[15]、一维声学黑洞法[16-17]、形态优化法在尖端区域粘结阻尼材料的方法完成减振[18].

采用渐变介质阻抗法引入连续渐变阻抗界面,在扶手架横杆处焊接空心管,原理是横杆加设空心管可以增加扶手架质量吸收一部分由支撑架传递上来的振动从而降低传递到人手处的振动能量. 采用一维声学黑洞理论方法,在支撑架与扶手架平板连接处加工出锥状结构,并在锥状结构表面附着阻尼材料(橡胶)吸收振动能量.

优化后扶手架的结构示意图如图 9所示,当整机工作时,振动能量汇聚到支撑架平板处,并经过扶手架传递到人手. 当振动能量信号传递到扶手架时,一部分汇聚到尖端部分,并被阻尼材料吸收,另一部分传递经过渐变阻抗阻尼材料层,振动能量进一步削弱,当传递到人手接触时,振动能量已经减轻了一部分,从而实现降低振动能量的目的,优化后扶手架质量增加1.25 kg,增加部分的质量需要通过优化支撑架来平衡.

-

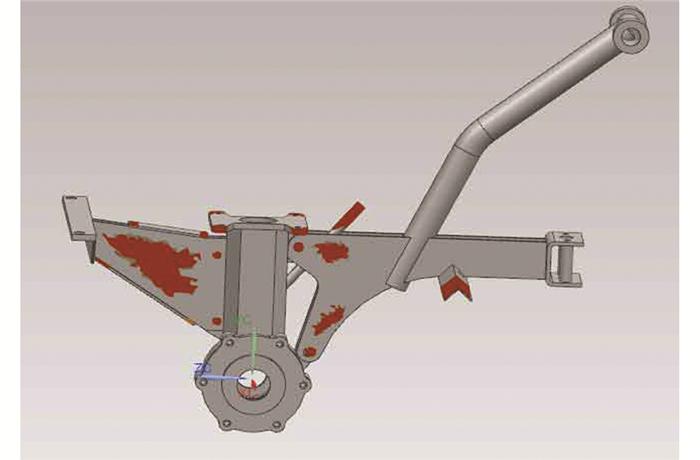

运用Ansys有限元方法对支撑架求解,优化云图结果如图 10所示,深色部分为可去除材料部分.

分析支撑架结构,可知前端支架处所受应力不大可以采用结构优化的拓扑优化方案,对前端支架进行镂空处理节省材料并减重,镂空处理后支撑架质量相对减少了1.43 kg,与扶手架增加的1.25 kg质量相近,保证了整机质量不变而不影响耕深.

-

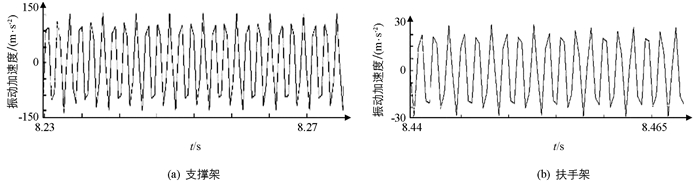

基于上面章节中建立的Simulink仿真模型,替换掉电动微耕机优化前的支撑架和扶手架结构并对电动微耕机进行优化后仿真,结果如图 11所示.

从仿真得到的RMS值可知,扶手架处RMS值为7.40 m/s2,支撑架平板处RMS值为66.84 m/s2,相对于支撑架和扶手架未进行结构优化之前的仿真结果,扶手架处RMS值降低了21.7%.

-

加工出优化后的支撑架和扶手架结构如图 12所示,并装配至电动微耕机上. 利用优化后的电动微耕机在前文试验的试验田进行优化后试验,所用仪器方法与前文试验一致,测得扶手架处RMS值为7.89 m/s2,支撑架平板处RMS值为59.58 m/s2,与仿真结果对比误差为6.6%,10.9%,与装配优化结构前试验相比扶手架处RMS值降低了24.5%.

2.1. 扶手架的结构优化

2.2. 支撑架的结构优化

2.3. 结果对比

2.4. 优化后试验验证

-

通过仿真与田间试验,验证了仿真模型建立方法的可行性,得出Matlab/simulink所建立的电动微耕机模型精确并可以反复使用,仿真与试验得出的扶手架振动RMS值均超过人手适宜的RMS值10 m/s2,需要对电动微耕机优化实现减振.

在仿真模型基础上,对扶手架与支撑架进行结构优化,并进行优化后的仿真分析,得到支撑架质量相对减少了1.43 kg,扶手架质量相对增加了1.25 kg,整机质量未发生大的变化;在优化仿真结果基础上,加工出优化后的支撑架和扶手架并进行装配,利用优化后的电动微耕机进行试验,测得扶手架处RMS值较优化前降低了24.5%,实现了电动微耕机减振的目的.

下载:

下载: