-

当前,我国农田已不堪重负,良田沃土退化、土壤污染、耕地地力下降、养分贫瘠等问题凸显,存在严重的生态环境和食品安全隐患.为应对这些问题,近年来,诸如护耕、休耕、农田涵养水源以及土壤增碳等计划逐步启动和实施[1-4].在土壤增碳方面,被学术界誉为“黑色黄金”的生物炭,已成为调理土壤健康的环境功能材料.它是由生物质在缺氧条件下经高温裂解生成的孔状固体物质,有较大的比表面积、较多的含氧活性基团及一些植物营养元素[5];其不仅具有改善土壤性质、提升土壤肥力、减轻土壤污染等农艺和生态功能[6-10],也是增加土壤碳汇、减少N2O和CH4等温室气体排放的技术选项之一[11-12].

《全国农业可持续发展规划(2015-2030年)》首次将“生物炭改良土壤”明确写入扶持政策范畴,与秸秆还田、深耕深松、积造施用有机肥和种植绿肥同列[13].可见秸秆炭化还田已具备市场化条件,建设生物炭产业是践行秸秆炭化还田理念的体现.但是目前生物炭产业在我国尚处于培育阶段,其制造多见于采用热裂解技术和水热炭化法在实验室和小型炭炉中进行[14-17],应用实例也多见于科研用途,未能在农业生产中大规模推广使用,这主要是因为面临着使用成本过高这一瓶颈问题[18-19].若能在田间直接将秸秆转化为生物炭,并应用于退化土壤的改良与污染环境的修复,不仅能够节省秸秆收集与前处理、制炭场地与设备运维、成品运输等环节费用,大幅降低制炭成本,又能够为提升地力、净化土壤、固碳减排等做出新的有益贡献[20].

本研究以黄河三角洲地区常见的农林生物质(棉花秸秆、芦苇、竹柳)为原料,探究将其在田间直接转化为生物炭的技术,以期获得性能稳定的生物炭产品.目的在于有效地降低生物炭的制备和使用成本,并为其制备和应用提供新的技术选项和思路——田间原位炭化还田.

HTML

-

本研究依托黄河三角洲地区,以当地林业局2016年冬季在林场、农田和滩地收集的该地区常见的竹柳、棉秆与芦苇等农林废弃物为生物质原料,于2017年8月,在东营市河口区仙河镇黄河三角洲综合训练基地农业开发利用试验场开展了田间“限氧喷雾”制备生物炭的方法探究试验.

-

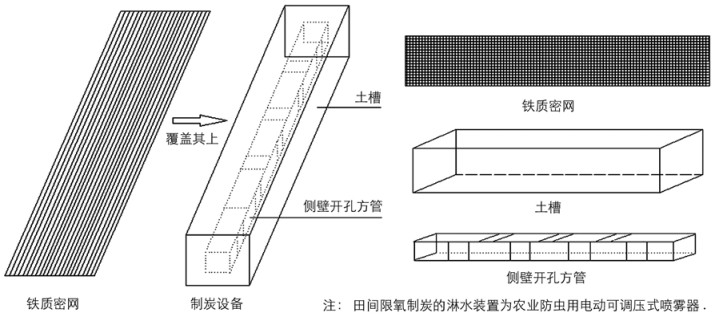

农林生物质田间限氧制炭槽体结构示意图如图 1.

1) 制炭土槽,规格:600 cm×30 cm×30 cm(长×宽×高);

2) 侧壁开孔的方管,方管规格:600 cm×10 cm×10 cm(长×宽×高),壁面开方孔,方孔规格:10 cm×10 cm(边长×边长),每面3~4个,方孔均匀分布在方管侧壁,通气孔率为4.33%[22];

3) 铁质密网:规格650 cm×80 cm,格网规格:0.2 cm×0.2 cm;

4) 喷雾装置:农用电动可调压式喷雾器;

5) 探温仪器:非接触式红外测温仪,型号:DT8833(北京华盛昌),量程:50~800 ℃,分辨率:0.1 ℃;

6) 其他辅助设备:铁锹、铁锚、砖块、固体酒精等.

-

1) 成炭率:生物炭的产率用炭化处理前、后物料干质量差的百分比进行计算;2)灰分含量:生物炭样品在马弗炉中经800 ℃条件下灰化处理4 h后其残余灰渣含量占总物料质量的百分比;3) pH值:生物炭与去离子水1:5混合(w/v,160 r/min下震荡24 h),静置,离心,过滤,待体系平衡后用pH计(Five Easy Plus,METTLER TOLEDO)测定;4)元素组成:元素分析仪(Vario Micro cube,德国Elementar);5)官能团含量:酸碱滴定法;6)比表面积的测定用氮气吸附BET法在全自动比表面积和孔径分布分析仪(AutosorbiQ,美国Quantachrome)上进行.

1.1. 供试材料与试验地点

1.2. 田间限氧制炭设备[21]

1.3. 生物炭的表征分析[23-24]

-

生物炭最早发现于巴西亚马逊河流域,这里分布着一层深厚而富碳的肥沃土壤,其农作物产量明显高于附近其他土壤.研究发现,这种土属人为土,是前哥伦比亚印第安人为了提高土壤肥力把各种农林垃圾烧成炭后施到土壤中,使得此区域的土壤成为整个亚马逊流域中最优质的土壤之一[25-28].这一发现激发了人们对生物炭研究的兴趣,揭开了生物炭研究的序幕.

本文田间“限氧喷雾”制炭的思路源于森林火灾生成的黑炭及关中平原一带农民针对冬季果树修剪后残枝落叶堆肥的启示.森林火灾被雷雨浇灭后会留下黑炭;在关中平原种植经果林的地区,农民在果园挖槽起垄,将冬季从果树上修剪下来的残枝落叶填入槽内并点燃,再将垄上土壤轻覆在槽面,待来年春天灌水,加速沤肥,以提升地力.春耕时可观察到土壤中混有焦黑色的粒状多孔物质.由此可见,在有火及水的情况下在田间制备生物炭是有可能的.

基于上述思路,我们设计了田间“限氧喷雾”制炭技术,经过多次实践筛选限氧方式和喷雾控温条件,并将制备得到的生物炭进行实验室表征,明确其特征性质.

-

1) 在田间挖掘600 cm×30 cm×30 cm(长×宽×高)的简易土槽,填充生物质原料(竹柳/棉秆/芦苇)至土槽体积的2/3处,压实. 2)随后将侧壁开孔的方管置于槽体的物料之上并居中放置(方管在物料填充至槽体2/3体积铺设,为较优的铺设部位.试验发现,方管填充至槽体中部不利于淋水后距离槽面1/3体积物料的燃烧,主要是由于淋水后槽面物料湿度增加,若通风不佳,则不利于燃烧). 3)继续填充农林废弃物直至与槽面平齐,压实. 4)将铁质密网平铺在槽面之上,用砖块固定.其中,侧壁开孔方管起到通气、限氧的作用,一方面解决了槽内深部秸秆燃烧的需氧问题,另一方面也有效控制了空气与物料的接触面积、调节物料的燃烧状况.铁质密网不仅为生物炭生成后的喷雾操作提供了通道;同时,喷雾过程会在铁质密网的格状微网表面生成水膜,限制了槽内物料与外界空气的接触面积,起到了限氧的作用;此外,铁质密网上在喷水操作过程中生成的水膜还可起到防止烟尘扬起的作用.田间“限氧喷雾”制备生物炭过程如图 2.

对于竹柳、棉秆等木质素物料,多为不规则柱状枝条,直径介于0.5~3.0 cm间,填充过程虽经多次压实,但依旧存在较大空隙,其制炭引火过程采用单侧引燃的方式进行.具体操作为,自槽体一端用固体酒精引燃物料,受热压差作用,明火会以类似于“退潮”的方式自引燃端向槽体另一端蔓延;适燃秸秆自火头部位约5~8 cm会发生弯曲上翘,并在重力作用下折断跌落;此时,开启电动喷雾器阀门,手持喷杆将喷头伸至跌落物上,喷杆的倾斜角度介于45°~60°之间,均匀喷雾至跌落的物体上,该物质便会由发黑泛红状态经短暂水雾后生成焦黑色的固态多孔物质.喷雾过程自引燃端至槽体另一端依据秸秆燃烧进程逐次进行,直至槽内秸秆全部生成生物炭后结束,此过程约需1.5~2 h,需水约8 L.

对于芦苇等纤维素类物料,多为规则的柱状中空/中虚壳体,直径在0.3~0.5 cm之间,填充压实后较为致密,空隙较少,单侧引火后燃烧部位仅为与空气接触面,且短时间后会自动熄灭.该类物料的制炭引火过程采用多位点引燃的方式进行.具体操作为,采用直径为3 cm的铁锚在槽面的铁质密网上沿槽长方向对称于侧壁开孔方管每隔50 cm钻取网孔1个,共计22个网眼,将固体酒精灌入网眼并引燃,火焰会迅速蔓延至槽内与空气接触的物料界面;此时,开启电动喷雾器阀门,调节喷杆角度,将喷头垂直放置在距离物料界面约20~30 cm处,并均匀喷雾至火焰上.火焰变小、暗火内延,并逐层引燃了槽体深部的秸秆.此燃烧过程中无明火,多见于红色蓬松状物质向槽内深部秸秆蔓延.这一现象的发生主要缘于如下作用:其一,喷雾器高压喷雾后火焰收缩,表层燃烧的秸秆温度降低、湿度增加,而深部秸秆则较为干燥、容易引燃,引起暗火内延现象的发生;其二,表层秸秆燃烧后与深层秸秆间产生热压差,加之侧壁开孔方管的通气作用,加剧了热压差的形成和空气流通,进一步促进了槽体深部秸秆的内燃.待芦苇秸秆自表层至内芯逐层受暗火引燃成炭后,均匀喷雾至火红色物质上,该物质便会经短暂水雾后生成焦黑色的固态蓬松物质,此过程约需3 h,需水约10 L.

采用非接触式红外测温仪探测结果显示,同槽物料不同部位的炭体(每1 m槽长内探测1次、共计6次)和同一物料分批入槽制得的炭(同一物料在同一槽体内以相同填充量分6次制炭)的成炭温度较为均一.竹柳秸秆的成炭温度介于323~375 ℃,棉花秸秆的成炭温度介于450~460 ℃,芦苇秸秆的成炭温度介于230~241 ℃.一般而言,物源一致的条件下,生物炭的性质主要受成炭温度影响[29-31].数据表明,田间限氧制炭的成炭温度表现出了较好的同槽均一性和异槽同质性,我们进一步对制备得到的生物炭进行实验室表征和性能比较分析,以明确采用此方法是否可获得性质稳定的生物炭产品.

2.1. 田间“限氧喷雾”制炭的思路起源

2.2. 田间“限氧喷雾”制炭的技术方法

-

表 1展示了农林生物质在田间经“限氧喷雾”技术制备的生物炭产品的基本理化性质,它们都呈现出了碱性pH值(7.99~9.21),这与传统用高温裂解装置制备的生物炭相似.同时,采用田间“限氧喷雾”技术制备的生物炭也表现出了较高的成炭率(26.3%~34.1%),保存了较多的营养元素N(0.44%~0.63%).更为重要的是,获得的生物炭产品的比表面积大(45.5~83.2 m2/g),含有丰富的表面官能团:羧基量介于0.71~1.43 mol/kg,酚羟基量介于0.43~1.09 mol/kg.因此,它们具备吸附剂的基本属性和较大的阳离子交换能力.本研究制炭过程中成炭温度较为稳定,说明采用该技术制备的生物炭质地较为均一.此外,生物质炭的成炭率在30%左右,也就是说,与秸秆直接焚烧相比减少了约1/3的CO2排放量.生物炭的基本理化性质分析结果表明,采用田间“限氧喷雾”技术制备生成的炭质材料是不同于秸秆直接燃烧生成的草木灰的.该方法的关键意义在于能够为生物炭的制备提供新的思路和技术选项,也首次证明了可以采用简单易行、成本低廉的方法在田间制备出生物炭.

-

我国理论生物质资源大约为50亿t/年,其中农作物秸秆10亿多t[20],其可再生性和有害物质含量低等属性使得生物质还田具有营养元素和有机质循环利用等生态学意义,但由于影响下季作物生长及病虫害增加等原因,秸秆还田实际上不容易推广,而秸秆炭化还田可提供新的技术选项;此外,随着新时代生态文明建设步伐的加快,城市园林废弃物处理问题也面临挑战.

本文提出的在田间制备生物炭的技术,主要通过“限氧喷雾”过程实现生物炭的制备.其中,竹柳和棉秆等木质素类物料采用单向引燃、逐次喷雾成炭的方式进行,芦苇等纤维素类物料采用多位点引燃、逐层喷雾成炭的方式进行.该方法成炭率高,且操作简单、易学,制成的生物炭产品性能稳定,含有丰富的表面官能团和较大的比表面积.

原材料的收集、运输及炭生产设备的购置与运行费用对生物炭生产商是一笔不少的开支(每吨生物炭成本大于1 000元),而炭成品的运输费进一步提高了生物炭的成本.高成本无疑限制了生物炭的规模化使用.田间“限氧喷雾”制炭技术突破了传统高温裂解技术需要建立工厂和炭炉来制备生物质炭的局限,规避了原材料和生物质炭产品的运输费用、省去了仓储成本、不需要昂贵的设备,制炭效率大幅提升且不再受场地的限制.该技术有望让农民在自己的地里用自家的农林生物质废弃物制备出低成本的生物质炭(200元/t),用于当地农业生产和土壤改良,做到就地取材、就地制备、就地使用,帮助实现提升地力、减轻污染等国家战略目标,也可将生物炭产品外销,变废为宝,增加农村就业,提高农民收入,服务乡村振兴战略.

DownLoad:

DownLoad: