-

南川大树茶是重庆地区的一种独特的地方品种资源,具有明显的原始特征[1],叶片大,节间长,角质层较厚,芽叶肥壮,且比当地多数中小叶种发芽早[2],有较高的开发利用价值. 2012年,“南川大树茶”获得了地理标志认证和地理标志证明商标,目前在南川区德隆乡茶树村已经形成了“南川大树茶扦插繁育、生产技术”等技术规范,大树茶仿原生态栽培技术初获成功[3].有关研究表明[4],南川大树茶属大叶种,儿茶素质量分数丰富,咖啡碱质量分数较高,推测南川大树茶适制红碎茶,滋味较好.

工夫红茶是中国特有的茶类,也是世界最早的红茶花色,是重要的出口茶类[5].近年来,红茶的消费量逐渐增长,传统工夫红茶的生产得以恢复,生产规模逐年扩大,引起茶叶界的重视.目前,关于工夫红茶适制品种以及加工过程的研究报道很多,但南川大树茶作为特殊的地方资源,关于其加工的研究却鲜有报道.因此本实验以南川大树茶1芽2叶为原料,加工工夫红茶,研究分析加工过程中感官品质、主要品质成分的变化规律,与当地栽培品种云南大叶种比较,分析两种茶的差异,挖掘南川大树茶的品质特色,并为确定大树红茶的最佳工艺参数提供一定的理论依据,促进大树红茶的生产加工利用.

HTML

-

2018年4月18日,大树茶采于南川市德隆乡南川大树茶示范基地,云南大叶种采于南川香炉寺山庄茶园,均为1芽2叶.

-

加工工艺流程按照鲜叶—萎凋—揉捻—发酵—干燥—毛茶,具体如下:

1) 萎凋温度:20 ℃~25 ℃,湿度:65%~75%,时长16 h,萎凋至含水量60%.采用型揉捻机,总揉70 min;发酵温度:26 ℃~28 ℃,湿度:85%以上,发酵200 min.将发酵叶投入热风杀青机2 min,至含水量30%左右.

2) 烘干机中100 ℃烘至足干.

-

采用微波杀青固样方式:微波高火1 min+1 min固定,然后80 ℃烘至足干.南川大树茶在每个工序分别取样,即鲜叶(dsc-1),萎凋叶(dsc-2),揉捻叶(dsc-3),发酵40 min(dsc-4),发酵80 min(dsc-5),发酵120 min(dsc-6),发酵160 min(dsc-7),发酵200 min(dsc-8),毛茶(dsc-9);云南大叶种毛茶样(CK).

-

按照GB/T 23776-2009《茶叶感官审评方法》[6].

-

按照GB/T8303-2013《茶磨碎试样的制备及其干物质含量测定》[7],GB/T 8305-2013《茶水浸出物测定》[8],GB/T 8305-2008《茶叶中茶多酚和儿茶素类含量的检测方法》[9]进行测定,茶红素、茶褐素的测定采用系统分析方法[10].

-

1) 标准曲线绘制:分别准确称取8种儿茶素组分、没食子酸、咖啡碱、茶黄素等标品各20 mg,用50%甲醇溶解,定容至25 mL容量瓶,得标准母液.吸取一定量的单标配制成混标,并稀释至不同梯度,分别进样分析,以峰面积为纵坐标,样品浓度为横坐标,绘制标准曲线.

2) 样品制备:参照GB/T 8305-2008《茶叶中茶多酚和儿茶素类含量的检测方法》[9].

液相色谱仪:赛默飞UltiMate3000,色谱条件:Ascentis © RP-Amide柱(5 μm,25 cm×4.6 mm),流动相A:体积分数为2‰的冰乙酸;流动相B:纯乙腈;检测波长:278 nm;温度:35 ℃;进样量:5 μL;流速:1 mL/min(表 1).

-

1) 标准曲线绘制:分别准确称取21种氨基酸标品各50 mg,用0.1 mol/L盐酸溶液溶解,定容至25 mL容量瓶,得标准母液.分别取100 μL配制成混标,稀释至不同梯度,取40 μL进行衍生,进样分析,以峰面积为纵坐标,样品浓度为横坐标,绘制标准曲线.

2) 样品制备:参照GB/T 8314-2013《茶游离氨基酸总量的测定》.

3) 氨基酸的衍生[11]:取200 μL茶汤,200 μL 2,4-二硝基氟苯溶液,200 μL Na2CO3-NaHCO3缓冲液(pH值为9.16),200 μL超纯水于2 mL离心管中,60 ℃暗水浴1 h,冷却至室温后加入800 μL KH2PO4-NaOH缓冲液(pH值为7.0),涡旋1 min,暗条件放置15 min,过0.22 μm水系膜,进样分析.

液相色谱仪:赛默飞UltiMate3000;检测条件:色谱柱AQ12S05-1546WT YMC-Pack ODS-AQ(5 μm,150×4.6 mm),流动相A:4 mmol/L乙酸钠溶液与四氢呋喃比例为96:4;流动相B:体积分数为80%的乙腈;检测波长:360 nm;温度:35 ℃;进样量:10 μL;流速:0.9 mL/min(表 2).

-

利用Excel,SPSS 18.0软件等进行单因素方差等分析.

1.1. 实验材料

1.2. 实验方法

1.2.1. 加工工艺

1.2.2. 取样固样

1.2.3. 感官审评

1.2.4. 水分、水浸出物、茶多酚、茶色素的测定

1.2.5. 儿茶素、没食子酸、咖啡碱、茶黄素组分的测定

1.2.6. 氨基酸组分的测定

1.2.7. 统计分析

-

将揉捻叶及之后各个工序的在制品进行感官审评,研究其品质变化.从表 3可知,随着加工的进行,青气逐渐减退,至发酵80 min(dsc-5)时开始透发出甜香、花果香,其中发酵结束时香气最好;汤色逐渐加深变为橙黄;各种内含物质转化,滋味慢慢变得甜醇,发酵80 min时滋味最佳,随着发酵时间的延长,茶汤逐渐带酸.相较之下,云南大叶种(CK)汤色更优,但香气不如大树茶,大树茶整体品质更优.

-

鲜叶(dsc-1)中水浸出物质量分数高达50.80%,发酵后降至最低值,烘干后又显著增加.鲜叶中茶多酚质量分数为22.50%,在加工中持续减少,毛茶(dsc-9)中保留量为14.18%,较鲜叶减少了36.98%.咖啡碱对大树茶红茶汤的鲜爽味有重要影响,从鲜叶到发酵初阶段,咖啡碱质量分数减少,发酵120 min(dsc-6)时降至最低,发酵结束(dsc-8)时达最大值5.16%,毛茶对比发酵叶和鲜叶质量分数差异有统计学意义(p<0.05).相较于云南大叶种,大树茶红茶水浸出物、茶多酚及咖啡碱质量分数更丰富.

萎凋叶经过揉捻,儿茶素即开始氧化,茶黄素、茶红素开始形成,在揉捻结束时,茶黄素质量分数已达到0.71%,在发酵初期继续增加,在后续发酵和干燥过程中变化幅度较小.茶红素在揉捻、发酵初期持续增加,发酵40 min(dsc-4)达到最大值5.15%,随后降低;而茶褐素质量分数在整个加工中持续增加,但是,总质量分数并不太高(表 4).相较之下,云南大叶种茶色素质量分数更高,但南川大树茶的茶黄素也明显高于国内川红、祁红等品种[12],甚至高于某些国外的红茶[13].

-

鲜叶中GA质量分数只有0.43 mg/g,萎凋过程中由于酯型儿茶素降解生成GA[14],因此质量分数显著增多,揉捻后达最大值4.00 mg/g,而后的工序中,由于GA氧化形成邻醌,与儿茶素类反应生成茶黄棓灵(theagallin)或茶黄酸[15]等,质量分数又逐步减少.

大树茶鲜叶中儿茶素总量为207.2 mg/g,其中酯型儿茶素比例高达88.44%,显著高于大多数云南大叶种,包括群体种和无性系良种[16].儿茶素总量随着加工的进行,质量分数持续减少,毛茶中保留量仅为30.8 mg/g.除GCG外,其余儿茶素组分质量分数在加工中逐步减少. EGCG在鲜叶中质量分数高达152.51 mg/g,占儿茶素总量的72.80%,加工后毛茶中保留量为12.50 mg/g,是云南大叶种的3.87倍. EGC和ECG两者变化趋势相同,加工中持续减少,最后烘干过程中略有上升. GCG在加工中质量分数明显增多(p<0.05),主要由EGCG差向异构化而来[17-18],发酵40 min(dsc-4)后达到最大值10.71 mg/g,毛茶中仍有8.04 mg/g,显著高于云南大叶种(表 5).日本学者坂本彬等[19]曾分析了来自4个国家的12个不同品种的红茶成分,发现大多数品种的EGCG保留量不足5.00 mg/g,而GCG均不足0.50 mg/g.相比之下,南川大树茶红茶中两者质量分数都很高,尤其是GCG,高于多数品种.

-

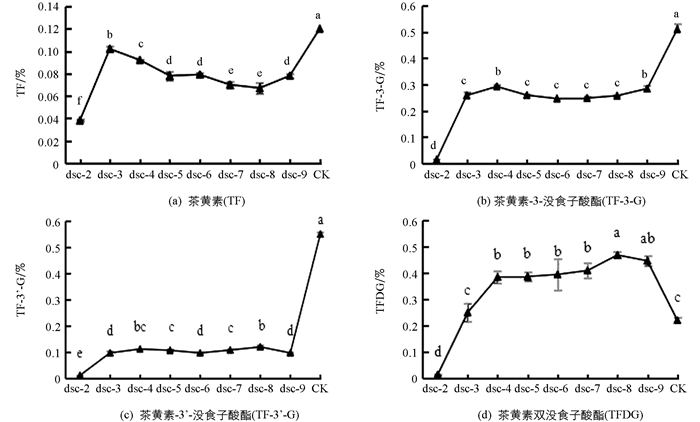

总体来看,TFDG是质量分数最高的组分,其次为TF-3-G,TF质量分数最低.由图 1可知,从萎凋到揉捻结束,各组分质量分数都急剧增加. TF在揉捻(dsc-3)时达到峰值0.1%,之后有所降低,毛茶(dsc-9)中有0.08%. TF-3-G,TF-3'-G从萎凋到发酵40 min(dsc-4)时质量分数显著增加,此时TF-3-G达到峰值,随后降低;TF-3'-G在发酵结束(dsc-8)时达到最高值. TFDG从萎凋到发酵结束,质量分数持续积累,发酵结束时达到最大值0.49%.大树茶TFDG质量分数明显高于云南大叶种,其余3种质量分数均低于云南大叶种.

Okinda等[20]证实TFDG与红茶品质呈极显著相关,不同茶黄素对红茶汤收敛性的贡献值不同[21].易晓芹等[22]分析了来自印度、斯里兰卡、肯尼亚等不同产地的15种红茶样茶黄素组分,发现TF-3-G质量分数均不足0.1%,TFDG质量分数也不高,相较之下,南川大树茶红茶中两者质量分数较为丰富,造就了红茶汤收敛性较强,滋味鲜爽的优良品质.

-

游离氨基酸在加工中的变化见表 6.鲜叶经萎凋后,由于各种水解酶的作用,蛋白质、多肽等水解,因此绝大多数氨基酸质量分数有所增加,其中苯丙氨酸、天冬酰胺等升幅较大,尤其苯丙氨酸相比鲜叶增加了7.49倍,天冬酰胺增长了3.44倍;游离氨基酸总量从24.11 mg/g上升到35.03 mg/g,增加了45.29%,之后的工序中呈现先降后升趋势,毛茶中为36.34 mg/g,质量分数显著高于鲜叶.鲜叶中质量分数较高的有茶氨酸、谷氨酸、丝氨酸等,随着后续加工的进行,茶氨酸在叶片中持续分解为谷氨酸和乙胺[23-24],因此质量分数降低;谷氨酸作为氨的转运站,可以进一步转化为重要的呈味氨基酸,质量分数也降低.脯氨酸、精氨酸等7种氨基酸在揉捻时质量分数有所增加,其余14种氨基酸均减少,此后的发酵过程有少量变化,但趋势较缓.发酵叶在烘干过程中,所有氨基酸质量分数均有增加,推测可能由于高温,蛋白质大量热水解,使得氨基酸质量分数增多[25].谷氨酸、茶氨酸、精氨酸、蛋氨酸这4种氨基酸在毛茶中的质量分数比鲜叶低,其余17种氨基酸在毛茶中的质量分数均显著高于鲜叶(p<0.05).

氨基酸在红茶加工中的变化较复杂,对红茶品质有重要影响[26].各氨酸经脱羧、脱水等生成了吡嗪类[27]、醛类[28]、吡咯类[29]等香气物质,使南川大树茶红茶透发出甜香和花果香.此外,氨基酸与多酚类氧化缩合形成的黑褐色物质[30],造就干茶乌润的色泽.大树茶红茶中茶氨酸[31]、天冬氨酸、丝氨酸[32]等质量分数较高,这些呈味氨基酸造就了大树茶红茶汤鲜爽[33]、甜醇[34]的优良品质.茶氨酸质量分数稍低于云南大叶种,但游离氨基酸总量更丰富,滋味更鲜爽醇厚.

2.1. 南川大树茶红茶加工过程感官品质变化

2.2. 主要品质成分在红茶加工中的变化

2.3. 儿茶素组分及没食子酸(GA)在加工中的变化

2.4. 茶黄素组分在红茶加工中的变化

2.5. 氨基酸组分在红茶加工中的变化

-

实验表明,南川大树茶鲜叶中儿茶素质量分数极丰富,且酯型儿茶素比例大,咖啡碱质量分数也较高,酚氨比大于8,且毛茶中茶黄素质量分数较高,氨基酸质量分数高,表明此品种适制红茶.在南川大树茶红茶加工中,水浸出物质量分数逐步减少,但毛茶中质量分数依然丰富,明显高于云南大叶种,符合优质红茶的标准.茶多酚和儿茶素类在加工中质量分数大幅减少,GA,GCG质量分数在加工中显著增加;TFDG在加工中整体呈上升趋势,是质量分数最高的组分,其次为TF-3-G;茶黄素总量呈上升—下降—上升趋势,茶红素质量分数先增多后减少,茶褐素持续积累,成茶中茶色素质量分数低于云南大叶种,游离氨基酸在加工中质量分数显著增加,质量分数较云南大叶种更高.云南大叶种汤色红亮,但香气、滋味等欠佳,大树茶红茶整体品质更优.

从南川大树茶鲜叶分析结果可看出,南川大树茶具明显的品种特征,鲜叶中EGCG质量分数极高,明显高于云南大叶种[35]、祁门种[36]、福鼎大白茶[4]、茗科一号[37]、四川中小叶种[38]等,在红茶加工过程中,高质量分数的EGCG分别与EC,ECG偶联氧化形成TF-3-G和TFDG,因此,毛茶中TF-3-G和TFDG的质量分数虽低于云南大叶种,但也较大多品种高.此外,EGCG转化形成大量的GCG,GCG也是红茶中的一种功能性成分,可减少血浆中的胆固醇,对脂质过氧化抑制能力很强,具有抗氧化活性,在某一特定条件下,清除自由基的能力甚至高于EGCG[39].

在后续的工艺优化过程中,可以通过对发酵叶的发酵温度、供氧状态、pH等因素加以调控和优化,抑制EGCG异构化为GCG,进一步促进茶黄素的形成,充分发挥南川大树茶的品种特性,提高产品品质.

DownLoad:

DownLoad: