-

近年来,烟草行业加快卷烟新产品、新品类的研发步伐,中支烟、细支烟、短支烟等一些非典型尺寸的卷烟密集涌现.与常规卷烟(长度84 mm,圆周24.0~24.4 mm)相比,中支、细支卷烟圆周大幅降低,辅材参数发生较大变化,如滤嘴通风率普遍较高、滤棒吸阻变大、丝束的单旦变大、总旦变小等.圆周大幅降低后,导致卷烟抽吸时空气流速大幅增加,燃烧锥处单位烟丝接触的氧气量会更高,导致卷烟的燃烧状态、烟气化学成分释放、过滤和扩散均与常规卷烟大不相同[1].卷烟圆周尺寸的变化对烟气常规成分、部分有害成分、香味成分及气溶胶粒径的影响,国内外研究较多,如Irwin等[1]研究了烟支圆周对主流烟气中焦油,烟碱,CO,NO,HCN,挥发性醛类的影响,Yamamoto等[2-3]考察了烟支圆周对焦油和烟碱及有害化学成分释放量的影响,葛畅等[4]考察了两种规格卷烟常规烟气指标及粒相物中中性致香成分的差异,Egilmez等[5]研究了细支卷烟和常规卷烟气溶胶粒径的差异.

滤嘴通风稀释是目前普遍采用的一种减害降焦的物理手段,主要通过接装纸预打孔或在线滤嘴打孔的方式实现.因此对于预打孔的接装纸,透气度是辅材参数设计的一项重要指标,其不仅影响卷烟的感官质量[6],而且是影响卷烟烟气常规成分释放量的显著因素[7].目前,对接装纸透气度影响常规卷烟的研究较多[8-13],对中支、细支卷烟的影响鲜有报道.本文拟对接装纸透气度与常规、中支、细支卷烟的感官质量、烟气常规化学成分及香味成分的影响进行对比分析,旨在为卷烟产品开发时针对不同规格的卷烟,科学合理地设计接装纸透气度参数提供参考.

全文HTML

-

以目前四川中烟规模产品使用的辅材为基准,分别设计常规、中支及细支卷烟接装纸透气度变化的样品(表 1),并统一使用四川凉山C2F等级单料烟丝进行卷制.

-

参考行业内目前在用的感官评吸方法[14],结合实际需求,制订了卷烟感官评吸方案.主要从3方面即香气特性、烟气特性和舒适感特性17个指标上进行评价,采用9分制进行打分,最小分值0.5.由7位评吸人员组成评吸小组,按照上述评吸表格对所用卷烟样品进行评吸,最终得分取7位评吸人员打分的平均值.

-

卷烟物理参数包括卷烟质量、吸阻及通风,烟气常规成分分析包括焦油、CO和烟碱释放量的分析,分析方法参考标准方法[15-17].卷烟样品烟气指标测试时,需将样品置于温度(22±1) ℃、相对湿度(60±2)%条件下平衡48 h,然后经质量(平均质量±0.015 g)及吸阻(平均吸阻±30 Pa)分选.

-

对卷烟主流烟气的香味成分进行分析,收集10支卷烟主流烟气粒相物的剑桥滤片一分为二放入4 mL样品瓶中,加入3 mL二氯甲烷萃取剂,并准确加入100 μL内标溶液(2 mg/mL),密封膜密封,超声萃取30 min,取萃取液,0.45 μm微孔滤膜过滤,滤液进行GC-MS分析,选择离子监测(SIM)定量分析检测目标成分.

1.1. 实验卷烟

1.2. 感官评吸

1.3. 卷烟物理参数及烟气常规成分分析

1.4. 烟气香味成分分析

-

常规、中支及细支卷烟不同接装纸透气度的物理参数测定结果显示(表 2),相同规格的卷烟质量一致,达到设计要求,且烟支圆周越小,质量越轻,所用烟丝越少.

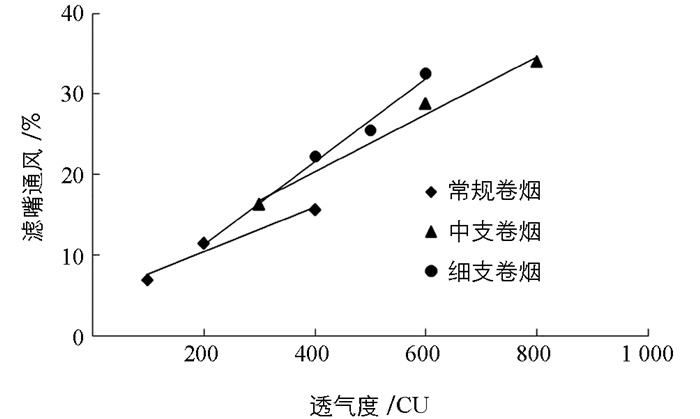

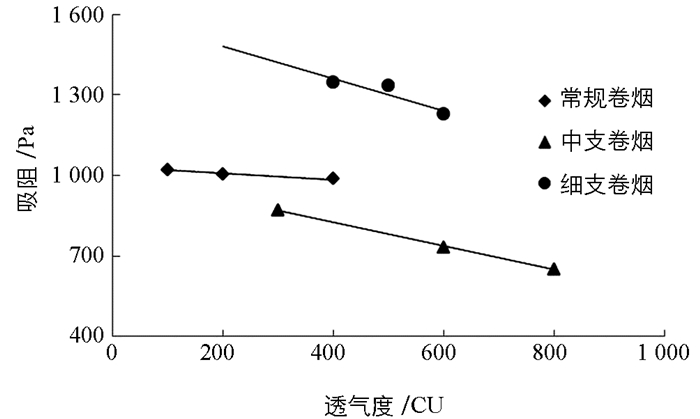

分别将常规、中支及细支卷烟的接装纸透气度与卷烟的吸阻、总通风率进行线性拟合,结果如图 1、图 2,表 3、表 4.可以看出,接装纸透气度同卷烟吸阻呈线性负相关关系,各规格的相关系数分别达到0.964,0.999,0.830,同卷烟的总通风率呈线性正相关关系,各规格的相关系数分别达到0.956,0.985,0.959.回归方程的斜率绝对值的大小反映了影响程度的大小,接装纸透气度对卷烟吸阻及总通风率的影响程度均随烟支圆周的降低而变大,其规律由大到小为细支卷烟,中支卷烟,常规卷烟.接装纸透气度每增加100 CU,常规、中支及细支卷烟的吸阻分别降低11.57 Pa,43.97 Pa,60.00 Pa,总通风率分别增加2.79%,3.57%,5.15%.

-

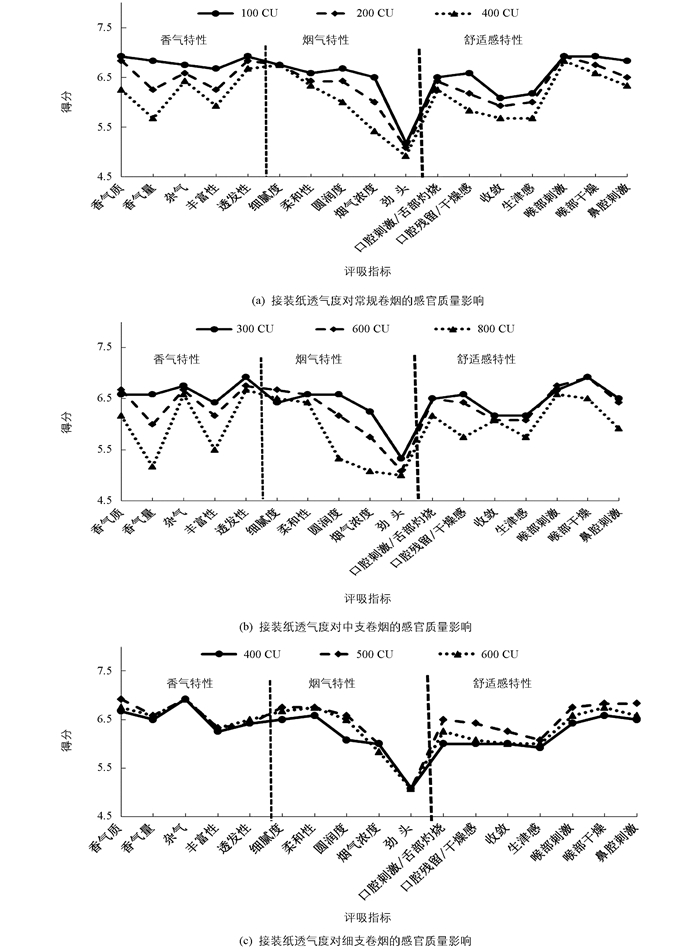

结果表明,接装纸透气度对常规和中支卷烟的感官影响均比细支烟显著,对常规及中支卷烟影响较大指标主要是香气特性的香气质、香气量、丰富性,烟气特性的圆润度及烟气浓度,舒适感特性的口腔残留/干燥感、生津感、喉部干燥及鼻腔刺激.

从感官质量得分上看(表 5),随接装纸透气度增加,常规卷烟和中支烟的感官质量总分均呈明显下降趋势,但对于细支烟,感官质量总分呈现先上升又略有下降的趋势.

-

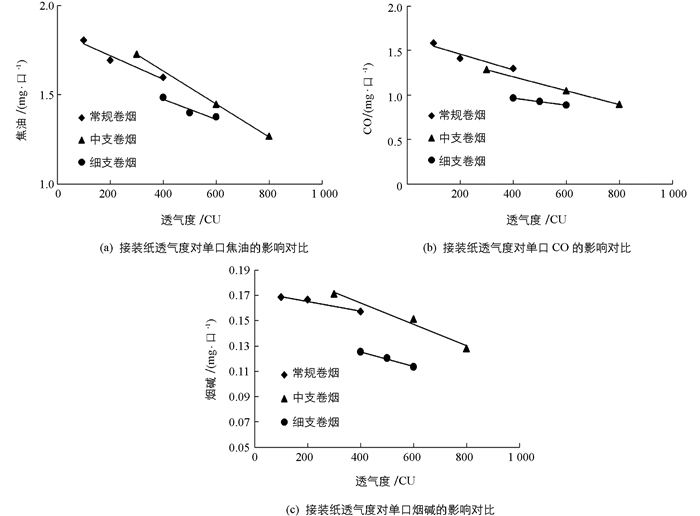

分别将常规、中支及细支卷烟的接装纸透气度与卷烟的单口焦油、单口CO及单口烟碱释放量进行线性拟合,结果如图 4、表 6.可以看出,接装纸透气度与卷烟的单口焦油、单口CO及单口烟碱释放量均呈显著线性负相关关系.从回归方程的斜率绝对值大小可以看出,接装纸透气度对常规及中支卷烟的单口焦油、单口CO的影响程度均大于细支卷烟,对中支及细支卷烟的单口烟碱的影响程度大于常规卷烟.接装纸透气度每增加100 CU,常规、中支及细支卷烟的单口焦油分别降低4.09%,5.49%,3.46%,单口CO分别降低6.18%,6.68%,4.33%,单口烟碱分别降低2.42%,4.82%,5.03%.

-

分别选取常规、中支、细支卷烟中接装纸透气度最小的样品,进行烟气化学成分分析,并分别计算出每克烟丝所释放的化学成分的质量分数,结果如表 7.

从表 7可以看出,各规格卷烟每克烟丝所释放的总量上,由大到小为中支卷烟(300 CU),细支卷烟(400 CU),常规卷烟(100 CU),常规卷烟较中支卷烟低20.1%,较细支卷烟低16.4%,常规、中支及细支卷烟的烟气化学成分总量依次为343.7 μg/g,412.8 μg/g,400.0 μg/g.从烟气化学成分的种类来看,所有规格的卷烟中酮类、酚类及醛类的质量分数均远高于其他类,三者之和占总量的70%以上,酸类及醇类的质量分数较低,二者之和只占总量的5%左右.

酮类、醛类及酯类随烟支圆周的下降而逐步升高,这是由于随着烟支圆周的下降,圆周与烟柱截面比值增大,抽吸期间更大比例的烟草与外部空气接触,导致更多的氧化反应,释放的酮类、醛类及酯类等羰基化合物较多[18].细支卷烟的酮类、醛类明显高于常规及中支,其中酮类分别高28.9%,5.1%,醛类分别高52.9%,16.8%.细支卷烟的酚类质量分数明显低于常规及中支卷烟,分别低16.8%,25.9%,因为烟草中糖类、多酚类、木质素和纤维素等是烟气中单酚化合物的主要前体[19],在无氧氛围下此类物质的产生量明显多于有氧氛围[20].细支卷烟与中支卷烟的烯类、酯类、呋喃类及醇类质量分数相当,高于常规卷烟11.7%~23.2%.细支卷烟与常规卷烟的氮杂环类、酸类相当,低于中支卷烟10.7%~16.6%.

2.1. 各规格卷烟物理参数对比分析

2.2. 接装纸透气度对常规、中支、细支卷烟感官质量的对比分析

2.3. 接装纸透气度对常规、中支、细支卷烟主流烟气指标的对比分析

2.4. 常规、中支、细支卷烟烟气化学成分的对比分析

-

接装纸透气度同卷烟吸阻呈线性负相关关系,同卷烟的总通风率呈线性正相关关系,影响程度均随烟支圆周的降低而变大.接装纸透气度每增加100 CU,常规、中支及细支卷烟的吸阻分别降低11.57 Pa,43.97 Pa,60.00 Pa,总通风率分别增加2.79%,3.57%,5.15%.

接装纸透气度对常规和中支卷烟的感官影响均比细支卷烟显著,对常规及中支卷烟影响较大指标主要是香气特性的香气质、香气量、丰富性,烟气特性的圆润度及烟气浓度,舒适感特性的口腔残留/干燥感、生津感、喉部干燥及鼻腔刺激.随接装纸透气度增加,常规和中支卷烟的感官质量总分均呈明显下降趋势,但对于细支卷烟,感官质量总分呈现先上升又略有下降的趋势.

接装纸透气度与卷烟的单口焦油、单口CO及单口烟碱释放量均呈显著线性负相关关系.对单口焦油、单口CO的影响程度常规及中支大于细支卷烟,对单口烟碱的影响程度中支及细支大于常规卷烟.接装纸透气度每增加100 CU,常规、中支及细支卷烟的单口焦油分别降低4.09%,5.49%,3.46%,单口CO分别降低6.18%,6.68%,4.33%,单口烟碱分别降低2.42%,4.82%,5.03%.

每克烟丝所释放烟气化学成分总量上,由大到小为中支卷烟(300 CU),细支卷烟(400 CU),常规卷烟(100 CU),常规较中支低20.1%,较细支低16.4%.所有规格的卷烟中酮类、酚类及醛类的质量分数均远高于其他类,三者之和占总量的70%以上,酸类及醇类的质量分数较低,二者之和只占总量的5%左右.酮类、醛类及酯类随烟支圆周的下降而逐步升高,酮类、醛类质量分数细支明显高于常规及中支卷烟,其中酮类分别高28.9%,5.1%,醛类分别高52.9%,16.8%.酚类质量分数细支明显低于常规及中支卷烟,分别低16.8%,25.9%,烯类、酯类、呋喃类及醇类质量分数细支与中支卷烟相当,高于常规11.7%~23.2%,氮杂环类、酸类质量分数细支与常规卷烟相当,低于中支卷烟10.7%~16.6%.

下载:

下载: