-

粮食安全是当今世界面临的主要全球挑战之一,粮食在储存期间的霉变占据了粮食损耗的主要部分[1].将水分降低至一定范围可有效缩减粮食在储存期间的霉变.其中,干燥是实际生产中降低粮食水分的最常用手段[2].

干燥是通过热能除去湿物料中水分的过程[3],其本质上是一种传热、传质耦合的现象[4],即物料在吸收热量的同时将水分以蒸汽的形式释放到外环境.随着市场的需求与科技的迅猛发展,大量的干燥方法涌现而出,如真空冷冻干燥、红外干燥、喷雾干燥等,近几年很多研究者将一种或多种干燥的方法并用,提出了联合干燥法的思想,然而粮食作物的干燥则更多依赖于热风干燥技术[5-6].

热风干燥有操作简单、成本低、对环境和场地设备要求不高等特点[7].为了进一步优化热风干燥的工艺,工程师们往往希望得到干燥过程中干燥设备内的温度、热风流速、湿度等物理量,但从实验中测量这些物理量是不经济的,甚至存在极大的困难.其中,温度与湿度属于标量物理量,测试相对简单,但是如果要得到温度场与湿度场的分布情况,则需要选取大量样本点进行测试,且样本点的数量将会随精度的要求呈指数式增长,这会导致实验成本与实验难度急剧增加;对于速度等矢量物理量,其本身测量就存在一定困难,而一定流域内速度场的测量则更加困难,甚至无法测量.因此,建立热风干燥过程的数学模型并通过计算机求解模型,获取所需要的物理量并观察干燥的物理过程,以优化热风干燥工艺是极其有必要的[8-11].

在过去的几年里,大量学者对热风干燥过程进行了研究,其研究结果大致可归为动力学模型研究与多物理场数学模型研究.动力学模型研究的主要内容一般是针对某种特定物料,在不同操作条件下直接进行实验,将实验结果按照Page模型、Logarithmic模型、Thomson模型等动力学模型进行拟合,并通过一定的分析手段得到该物料的最佳干燥条件或最佳干燥动力学模型.贾敏、齐娅汝、孙悦等分别研究了鲍鱼、二至丸、紫薯的干燥过程,得到了其最佳动力学模型,或最佳干燥条件[12-14].该类研究具有较强的针对性,在确定特定物料干燥条件时有一定优势,但是其拓延性较差,对于不同物料需要重新进行实验.多物理场数学模型研究的主要内容是针对物理模型,经过一系列抽象与假设后,直接用数学方程来描述物理过程,最后通过计算机软件求解数学模型以获取物料在干燥过程中的各项物理参数,具有较好一般性与优良延拓性.李艳等建立了仓内稻谷热风干燥的多尺度多层结构的热质传递模型,并较好地预测了稻谷的干燥过程,但其将温度边界条件直接设置为热风温度,只考虑了稻谷内部的热质传递,忽略了干燥仓内的传热传质过程[15];陈磊等以海绵为材料对多孔介质干燥过程进行了模拟,但其只考虑了海绵内部湿热传递情况,忽略了海绵外部环境的传热传质过程[16];刘洋等将马铃薯块视为多孔介质,建立其对流干燥的多场耦合模型,使用COMSOL软件对模型进行了求解,得到了干燥过程中温度、含湿量、水分质量等参数,但是该模型是以马铃薯为研究对象,并未考虑马铃薯外部环境中物理量的变化情况[17];王会林等基于菲克扩散定律、傅立叶导热定律和热弹性理论构建了含湿多孔介质中热—湿—力双向耦合的多场模型,并将模型应用于马铃薯块与胡萝卜块,同时分析了环境因素对干燥过程的影响,但是并未考虑物料外环境中的物理过程[18];Onwude等建立了红薯的热风红外联合干燥模型,较好地预测了红薯的干燥过程,但其直接以热流量为边界条件,忽略了干燥室内的传热传质过程[1];此外Salagnac、Jaturonglumlert、Datta、Kumar等人针对不同干燥方法建立了多种多场耦合模型并将模型应用于不同的物料,证实了模型的可行性,Kumar还考虑了物料干燥过程的收缩,对以往的模型进行了进一步的拓展[19-22].不难看出,国内外学者在物料干燥的多场耦合模型上已经取得了丰厚的成果,但是已有模型大都是针对被干燥物料而建立的,极少考虑到物料外部环境中热质传递情况.

基于上述情况,本文引入流体动力学方程组描述物料外部区域热风流场变化规律;对物料外部区域应用热力学第一定律,建立了其能量传递控制方程,通过密度、黏度两个物理量建立了流体动力学方程组与热传递方程之间的耦合关系,通过达西渗流定理和菲克扩散定理将物料外部与内部的物理方程联系起来.综上所述,本文在前人的基础上进一步完善了热风干燥模型,使得模型能够更加贴切地描述实际干燥过程,模型计算结果对干燥设备的设计优化有指导作用.

全文HTML

-

干燥是一个极其复杂的热物理过程,物料内部同时发生着热量、质量的传递[23].大量研究者着重于物料内部传递机理的探究却忽略了物料外部环境对干燥过程的影响,然而对于风干燥,考虑物料外部热量、质量传递是极其有必要的.干燥理论的发展历程中,物料通常被视为多孔介质[24],本文仍然延引了多孔介质模型,并考虑物料外部影响.

-

物料外部环境的热量传递依赖于空气流动,空气流动遵循流体力学基础方程,其形式如下:

式中ρa表示空气密度,kg/m3;ua表示空气运动速度,m/s;p表示压力,Pa;μ表示空气动力黏度,Pa·s;F表示体积力,N/m3;t表示时间,s.

式(1)是流体的连续性方程,其本质是质量守恒定律.式(2)是流体的动量方程,其本质是牛顿第二定律(动量守恒定律).

当流场方程作用于物料内部区域时,需要根据物料属性对式(1)、式(2)进行处理.本文将被干燥物料视为多孔介质,采用体积平均的思想对式(1)、式(2)进行处理[25],可得如下方程:

式中ε表示(多孔介质)物料的孔隙率.式(3)、(4)可用于描述物料内部的气体运动规律.但考虑到多孔介质中流体流动有渗流作用,即达西流,因此仍需对方程进行修正,根据Datta所述达西流引起的作用可表示成如下形式[26]:

式中k表示物料渗透率,m2.

将达西流作用插入到式(4)可得:

式(3)、(6)可直接用于物料内部气体流场的计算.

考虑到空气可压缩且其密度受温度影响,所以式(1)、(2)、(3)、(6)中的密度ρa均需要重新计算.根据气体状态方程可导出如下方程:

式中p表示压力,Pa;p0表示大气压,101.325 kPa;T表示绝对温度,K;T0为常量,273.15 K.

同样地空气动力黏度μ也是变量,研究表明空气动力黏度与温度有显著关系,而与压力几乎无关.在温度小于2 000 K时,空气动力黏度可按照萨特兰公式计算[27]:

式中μ0表示15 ℃时的空气动力黏度,1.7894×10-5 Pa·s;B为常数,110.4 K.

-

热风干燥过程中的热传递现象是极其复杂的.热风携带热量从干燥设备入口进入,流经物料表面并将热量传递给物料;在对流、传导、辐射等各种热物理现象的作用下,热量逐渐传递至物料内部,使液态水蒸发为气态.该过程涉及到一系列复杂的热传递现象,但根据刘伟等所述,由热辐射引起的热量交换可忽略[28],因此本文仅考虑由对流、传递现象引起的热量交换.根据能量守恒定律可得物料外部区域热量传递的微分方程,其形式如下:

式中ρa表示空气密度,kg/m3;cp表示空气比热容,J/(kg·K);λ表示空气导热系数,W/(m·K);q表示内热源项.

式(9)表明了温度变化率与能量之间的关系,方程左边第一项是能量变化率,第二项是由对流作用引起的热量交换,其中速度场ua即为1.1中所求解的速度场;方程右端第一项表示由于传导现象引起的热量交换,第二项表示内热源,即介质内部产生的热量.需要注意的是式(9)中的密度ρa仍为变量,需按照式(7)计算.

当热量传递方程作用于物料内部区域时,热传递介质由单一的空气变为湿空气、液态水、固体骨架3种,因此需要对式(9)进行修正.根据Datta所述[26],并考虑到物料内部液相蒸发为气相时需要吸收热量,式(9)可修改为如下形式:

式中γ表示水的蒸发潜热,J/kg;I表示液相单位体积蒸发速率,kg/(m3·s);下标eff表示各物理量有效值.

式中S表示饱和度;下标s、l、g分别表示固、液、气相.式(11)、(12)实质是对多孔介质物料的各项物性参数进行了加权平均,从而获取了对物料的整体描述效果.

根据Halder所述,任意体系中各组分的饱和度之和为1[29],因此针对本文所讨论情况有:

-

物料外部的水蒸气传递由空气流动与自身扩散两部分共同作用,假定扩散现象服从菲克扩散,以质量守恒定律为基础,可以得到如下控制方程:

式中cv表示水蒸气浓度,mol/m3;D表示扩散系数,m2/s.方程左边第二项是由菲克定律作用的扩散传递,第三项是由于空气自身流动引起的传递,该项中速度场ua直接由式(1)、(2)计算.

物料内部气相传递的质量控制方程为

式中utot表示物料内空气迁移的总速度,m/s;R为源项,是由液态水蒸发引起的. Bixler认为蒸发速率与梯度势有正比关系[30],但多孔介质中水分蒸发速率受介质内含水率制约,因此R可写成如下形式:

式中Kevap为常数,1/s;cv_sat表示饱和蒸汽浓度,mol/m3;aw表示水活度.

式(15)中的utot表示空气运动的速度场,但是此处并不能按照式(3)、(6)直接计算.物料内部空气流动受多孔介质固体骨架影响,使空气在多孔介质内部存在一定程度扩散,因而物料内部的气相传递作用机理极其复杂,受到自身流动、扩散、渗透、毛细等共同作用[31].对于热风干燥而言,物料内部气相传递主要受到自身流动及扩散影响,因而物料内部空气迁移总速度可表示为

式中ua表示空气自身流动速度,m/s;udif表示空气自身扩散速度,m/s.假定空气扩散仍服从菲克定律,则其通量可表示成如下形式:

式中J表示扩散通量,mol/(m2·s);ca表示空气浓度,mol/m3.扩散通量与扩散速度的关系可表示成:

式中M表示物质摩尔质量,kg/mol.

将式(18)、(19)带入式(17)可得物料内部空气迁移总速率:

其中ua由式(3)、(6)直接计算.

-

液相传递现象只发生在物料内部区域,其扩散控制方程形式上与式(14)一致,但考虑到实际物理过程中液相总是蒸发成气相,所以液态传递中具有与气相方程中对偶的源项,即数值上与式(15)的一致,但符号相反.液相传递方程形式如下:

式中ul表示液态水的运动速度,m/s.

根据达西定律ul可表示为:

式中k表示渗透系数,m2.压力p直接由式(3)、(6)计算得到.

1.1. 热风流场计算

1.2. 温度场计算

1.3. 气相传递模型

1.4. 液相传递模型

-

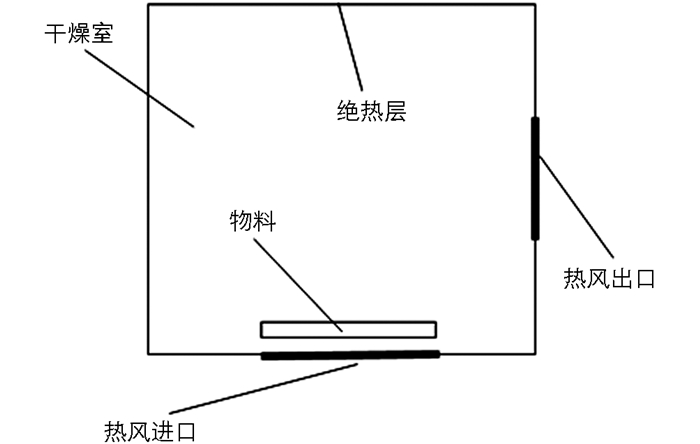

本文采用长春吉大科学仪器设备有限公司生产的BC-2型薄层干燥试验台进行模型验证[32],以验证计算结果.实验所用BC-2型薄层干燥试验台的干燥箱结构如图 1.

干燥室内腔尺寸为0.4 m×0.4 m×0.4 m,热风进口尺寸为0.15 m×0.15 m,热风出口(排湿口)直径为0.1 m,放置物料的托盘尺寸为0.18 m×0.18 m,物料堆放高度h根据实验安排确定.

实验以油菜籽为干燥对象,购买时油菜籽的含水率为7.50%db,按照文献所述加湿方法对其进行加湿[33],加湿后的含水率为17.92%db.每次实验取加湿后样品200 g(误差0.01 g),即油菜籽的初始质量为200 g,重复3次实验,测量结果取平均值.实验环境温度为27 ℃,进口热风温度55 ℃,油菜籽堆放高度为0.011 m,进口热风速度0.9 m/s.

基于上述物理参数,采用Comsol Multiphysics商业软件对干燥模型进行求解,数值求解时所需参数值见表 1[29, 34-35].

-

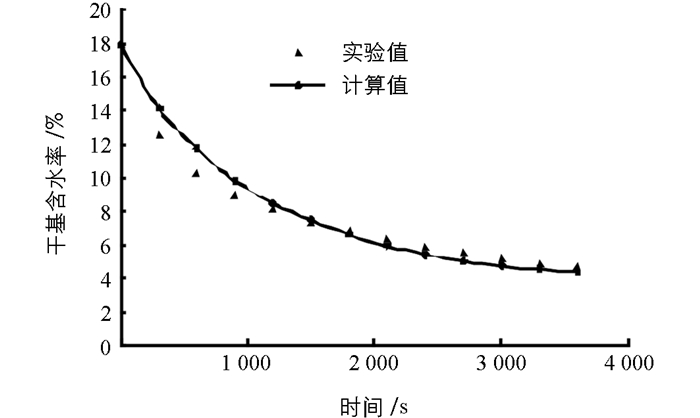

通过实验和数值求解,得到油菜籽的干燥特性曲线,如图 2所示.从图中可以看出,油菜籽的含水率随时间大致呈指数关系下降,计算值与实验值基本吻合,误差最大值出现在第二个测量点处,相对误差为13.3%,绝对误差为0.016,其相对误差偏高是因为第二个测量点的基数过小,其计算相对误差时的分母过小引起的,但是其绝对误差仅为0.016,因此本文构建的干燥模型是可行的.经过分析,误差产生的原因主要有以下两个方面:一是实验与模拟情况不完全一致,建模过程中引入了大量假设,并忽略了一些次要因素;二是模拟计算过程中采用了部分经验关系,其精度会直接影响模型计算结果.

-

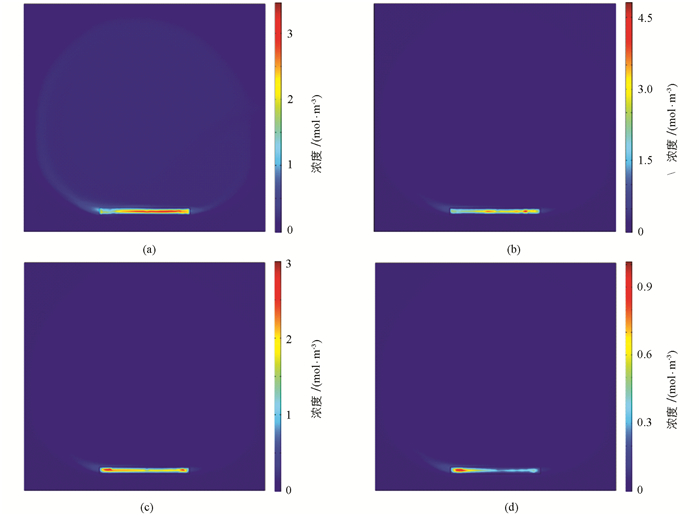

通过数值求解可以得到油菜籽干燥过程中干燥室内水蒸气的分布云图,如图 3所示.图(a),图(b),图(c),图(d)分别表示300,600,1 200,2 400 s时的水蒸气分布情况.从图中可以看出干燥室内靠近壁面的区域水蒸气浓度最低,中心区域较高,油菜籽堆放区域水蒸气浓度最高,水分蒸发发生在油菜籽堆放区域,故该区域水蒸气浓度最高;在扩散作用下,水蒸气由油菜籽内部迁移至表面,然后被热风携带排出干燥室,干燥室内靠近壁面区域的热风风速较高(见3.5节),故水蒸气迁移速率高,残留量低;干燥箱中心区域热风风速几乎为0,该部分水蒸气无法及时排出,故该部分水蒸气浓度比干燥内靠近壁面区域高.

-

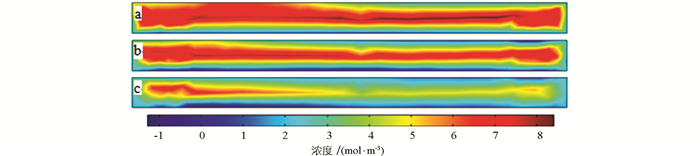

通过数值求解得到物料内部水分分布云图,如图 4所示. a,b,c分别为300,600,1 200 s时的水分分布情况.图中红色区域是湿区,该区域水分存在方式以液态为主;蓝色区域是干区,该区域液态水含量相对较低,水分主要以气态方式存在;黄色区域是蒸发区,该区域内液态水不断蒸发成气态.对比图中a,b,c可知油菜籽的整个干燥过程是由外向内逐渐进行的,其蒸发面逐渐由外向内迁移,这与Metzger提出的干燥过程存在蒸发面迁移现象和干燥物料存在干区和湿区的研究结果一致[36],进一步说明了本文所构建的干燥数学模型的可行性和有效性.

-

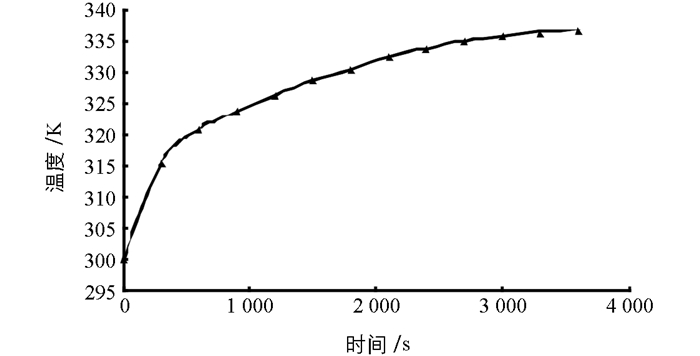

通过数值研究得到干燥室内物料的温度变化曲线,如图 5所示.从图中可以看出被干燥物料的温度随时间上升,最终趋于热风温度,此温度变化规律与实际吻合.开始阶段,物料的平均温度上升迅速,此时物料自身温度较低,温度梯度较大,热传递现象剧烈,此阶段可以认为是物料的预热阶段;大约经过300 s的预热之后,物料平均温度上升温度趋于平缓,最终接近恒定值,说明在干燥的中后期,热风所携带的热量大部分被从排湿口排出,并未被物料有效吸收.因此在干燥中后期,在保持物料温度基本稳定的情况下,可适当降低热风温度,以达到节能减排的效果.

-

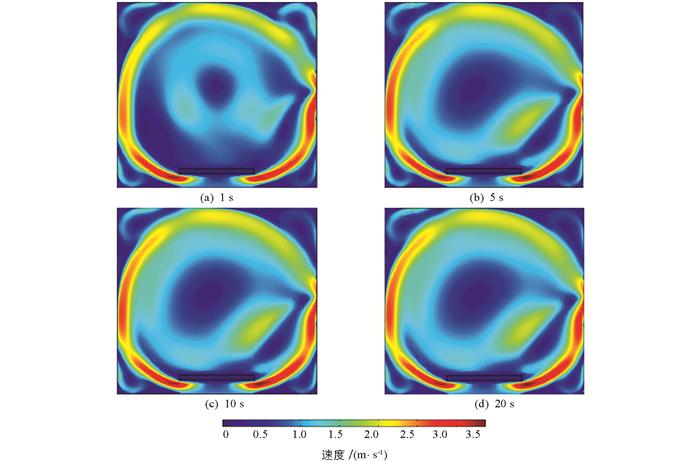

通过数值研究得到干燥室内热风风速云图,如图 6所示.

(a),(b),(c),(d)分别为1,5,10,20 s时热风风速云图情况.由图(a),图(b)可知1 s时刻干燥室中心区域流场有微量扰动;由图(b),图(c)可知5 s时刻干燥室内热风流场开始趋于稳定;由图(c),图(d)可知10 s和20 s时刻干燥室内部热风流场基本一致,这说明在很短时间内干燥室内部的热风流场就已经趋于稳态.在实际工程问题求解中,可先进行流场的稳态求解,然后再以该稳态解去计算能量与质量传递方程.该操作方法实质上是把流场与其它场的强耦合关系转化成了弱耦合关系,牺牲了一定的计算精度,但是该方法避开了流场的瞬态计算问题,极大地节约了计算成本,并且不会造成计算结果的较大偏差.因此工程领域在进行类似的分析计算时,可以先计算流场的稳态解,然后再计算其余物理场.

3.1. 油菜籽的干燥特性曲线

3.2. 干燥室内水蒸气分布

3.3. 物料内部水分分布

3.4. 干燥室内物料温度变化曲线

3.5. 干燥室内热风风速分布

-

本文根据多孔介质在热风干燥过程发生的多物理场变化,运用流体动力学方程描述了干燥室内热风的变化情况,根据质量、能量守恒定律建立了多孔介质热风干燥过程的质量、能量传递方程,并以油菜籽为物料进行了热风干燥实验,使用商业软件Comsol Multiphysics模拟出了实验条件下油菜籽含水率变化情况、干燥室内水蒸气浓度变化情况、干燥室内流场变化情况、油菜籽含水量分布变化情况、油菜籽平均温度变化情况,研究结果表明:

1) 模拟值与实验值最大误差为13.3%,表明本模型可信;

2) 油菜籽在干燥过程中有干区、湿区、蒸发区之分,且干区与湿区被蒸发区隔开,蒸发区逐渐由物料外部向内部迁移;

3) 干燥室内水蒸气浓度总体上先增大后减小,干燥室中心区域水蒸气浓度比干燥室边缘区域水蒸气浓度高,表明干燥过程中干燥室内中心区域水蒸气无法及时排出,这不利于干燥过程进行,说明干燥室有待进一步优化;

4) 干燥初期,油菜籽平均温度上升迅速,表明油菜籽在干燥过程中存在着预热阶段;

5) 干燥室中心区域热风风速比边缘区域热风风速低,热风流场在极短时间内达到稳态,说明在工程计算时可采用流场的稳态解进行能量与质量传递方程的求解,并且不会对计算精度造成过大影响.

下载:

下载: